Break Free from Daily Chaos: The First Steps Towards Operational Excellence

If you walk onto most manufacturing floors in the UK, beneath the hum of machinery and the focused energy of the team, there’s often a current of something else: a low-grade, persistent chaos. It’s the missing tool, the urgent order that throws the schedule out, the pallet of raw materials that arrived late again. It’s the small, daily fires we’ve become expert at putting out. But what if we could prevent the fires from starting in the first place? That’s the shift we all would want.

In today’s world, especially in the UK with its unique set of pressures, operational excellence isn’t just a buzzword. It’s the bedrock of survival and success. It’s about moving from reactive chaos to proactive clarity, where processes are so smooth, predictable, and efficient that they give you a competitive edge. This isn’t about unattainable perfection; it’s a journey; a series of deliberate steps toward better processes, higher quality, and a more engaged team. And it starts with the first, simple step.

Understanding the Foundations: What Are We Actually Talking About?

Before rearranging the factory floor or buying new software, we need to understand what ‘operational excellence’ means. Ask ten managers, and you might get ten answers. For me, it boils down to one idea: consistently and reliably delivering value to your customers.

It’s not about heroic efforts to hit a quarterly target. It’s about building a system and culture where everyone is involved in making the business better every day. It’s the quiet, relentless pursuit of improvement.

So, what are the pillars holding this idea up?

First, there’s process improvement. This is the nuts and bolts of it all. It’s looking at how you do things, from the moment an order comes in, to the moment a finished product goes out, and asking: “Is there a better way?” Frameworks like Lean Manufacturing focus on eliminating waste, while Six Sigma reduces variation and defects. But you don’t need to be a black belt to start. It can be as simple as noticing that an operator walks twenty feet to get a spanner ten times an hour. Fixing that is process improvement.

I remember a place I worked at years ago. An assembly line was always behind schedule. Management’s solution was to throw more people at it, which created more confusion. I simply observed the process for a shift. I found that a critical component was stored on the other side of the workshop. The time spent walking back and forth added up to two hours per shift. By relocating a storage bin, I increased output by nearly 15%. That’s process improvement: noticing the obvious things we’ve become blind to.

Next are quality management systems (QMS). Yes, ISO 9001 audits and paperwork can feel bureaucratic, but at its heart, a good QMS is your company’s rulebook. It ensures consistency, preventing one shift from doing a task one way and another shift doing it differently. It’s your defence against defects, recalls, and unhappy customers. Think of it as the DNA of your operational reliability.

Finally, the big one: a culture of continuous improvement. In Japan, it’s Kaizen. It’s the belief that everything can be improved and that the people closest to the work are best positioned to figure out how. This requires a cultural shift for many traditional manufacturing businesses. It means moving away from a top-down, ‘I talk, you listen’ model to one where everyone feels able, and obligated, to flag problems and suggest solutions.

To get any of this off the ground, you need a clear vision. What does excellence look like for you? Is it reducing your defect rate from 3% to 0.5%? Cutting lead-time in half? Achieving 99% on-time delivery? Define it, write it down, and talk about it relentlessly. Your vision becomes the North Star guiding every decision, project, and conversation about improvement.

The Honest Reality Check: Finding Your Starting Point

You’re sold on the vision. You want that smooth, efficient, high-quality operation. The next step is a dose of cold, hard reality. You need to understand exactly where you are right now, warts and all. It can be painful, but it’s essential. You can’t draw a map to your destination if you don’t know your current location.

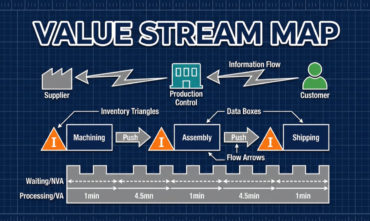

Start with a value stream mapping exercise: follow the flow of value through your processes, beginning to end. Gather your team in a room—the shop floor supervisors, the sales experts, the finance director—everyone who shapes or moves that value.

- Current State Analysis: Where does value stall, bottleneck, or get lost? Are there outdated systems, communication gaps, or rework loops? Capture every handoff, every delay, every friction point. This is a no-blame exercise, it’s about identifying problems, not assigning fault.

- Value-Adding Steps: Where is the magic happening? Skilled workers? Effective workflows? Pinpoint and preserve what drives quality and efficiency.

- Non-Value-Adding Steps: Shine a light on waste. What slows you down, bloats your cycle times, or eats resources without adding impact?

This gives you a vivid, real-world picture of how value moves through your operation, and where it stalls. With this clarity, you’re ready to flow forward, reimagine, and reorganise for maximum efficiency.

Next, back it up with hard data. Gut feelings are great, but data tells the truth. Start with a few Key Performance Indicators (KPIs) that matter. A good starting point in manufacturing is Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality. You might find a machine you thought was running flat out actually has an OEE of 50%, which is typical.

Other crucial metrics include scrap rates, on-time delivery percentages, and customer complaints. Establishing a baseline gives you a starting line. Every improvement can be measured against this baseline, proving its value.

But data is only half the story. The other half is in the minds of your people. You must engage your employees. They know what works, what doesn’t, and what drives them crazy. How do you get this information? Do ‘gemba walks,’ a Japanese term meaning ‘go to the real place.’ Walk the factory floor, watch processes, and talk to operators. Ask simple questions: “What’s the most frustrating part of your job? If you had a magic wand, what’s the one thing you’d change?”

Set up regular team huddles or suggestion boxes. Crucially, when people give feedback, act on it, or explain why you can’t. If suggestions disappear into a black hole, people will stop making them. But if they see their ideas lead to real change, you’ll unlock a flood of innovation.

Making the First Moves: From Ideas to Action

You have your vision and baseline. Now it’s time to get your hands dirty. Start small, aim for quick wins, and focus on changes with the biggest impact and least disruption.

A great place to begin is by streamlining workflows and reducing waste. This is the heart of Lean thinking. The “8 Wastes”—Defects, Overproduction, Waiting, Non-Utilised Talent, Transportation, Inventory, Motion, and Extra-Processing—are a great lens for viewing operations. Teach them to your team.

A brilliant first project is a 5S campaign: Sort, Set in Order, Shine, Standardise, Sustain.

- Sort: Remove unnecessary items.

- Set in Order: Find logical, ergonomic homes for everything.

- Shine: Clean the area to make problems like leaks or loose bolts visible.

- Standardise: Create rules to maintain the new state.

- Sustain: Make it a habit.

A 5S project is visual, involves everyone, and delivers immediate results in efficiency and safety. It proves change is possible and builds excitement for what’s next.

Next, integrate quality management tools and feedback loops. When something goes wrong, do you just fix the immediate problem and move on? That’s firefighting. To achieve excellence, you need to become a detective. Use the ‘5 Whys’ to find root causes (I’ll add here it doesn’t take five, it’s normally way more than that). For example:

- Why did the machine stop?

Because a fuse blew. - Why did the fuse blow?

Because the motor overloaded. - Why did the motor overload?

Because the bearing wasn’t turning smoothly. - Why wasn’t the bearing turning smoothly?

Because it wasn’t properly maintained (e.g., lubricated or replaced as needed). - Why wasn’t it maintained properly?

Because it wasn’t included in the maintenance schedule.

Extending Beyond 5 Whys: - Why wasn’t it included in the maintenance schedule?

Because the organisation lacked a standardised process for auditing and updating maintenance schedules. - Why does the organisation lack a standardised process?

Because preventive maintenance policies have not been prioritised or formalised.

Instead of just replacing a fuse, you prioritise preventative maintenance and policies—a permanent solution. This is a feedback loop: using failures to strengthen processes.

Finally, empower your employees. Give them the training, tools, and authority to make decisions about their work. Trust a production cell to manage its own quality checks or let a team leader sequence jobs. This shift from director to coach can be scary for traditional managers, but it fosters pride and ownership, transforming results.

Don’t forget your supply chain. Even the most efficient factory is vulnerable if components don’t arrive on time. Build stronger relationships with key suppliers, explore dual sourcing, and improve forecasting. In the post-covid landscape, a resilient supply chain is not just an advantage, it’s a necessity.

The Journey, Not the Destination

The path from manufacturing chaos to operational excellence can feel daunting. But you don’t climb a mountain in one leap; you do it one step at a time. By understanding the foundations, conducting an honest assessment, and implementing targeted first steps like a 5S project or the 5 Whys, you build momentum. You prove to yourself and your team that change is possible, and beneficial.

Operational excellence isn’t a final destination. It’s a continuous journey of improvement; a mindset embedded in your culture. The benefits—enhanced efficiency, superior quality, higher productivity, and an engaged workforce—are real and compound over time. Start small, be consistent, and position your operation for the sustained success it deserves in an increasingly competitive world.

To truly embed operational excellence, consider the broader implications of your efforts. This journey is not just about internal processes but also about how you interact with the external environment. Engage with industry forums and networks to share best practices and learn from others. This external engagement can provide fresh perspectives and innovative ideas that you might not have considered. Additionally, consider the role of technology in your journey. The digital transformation of manufacturing, often referred to as Industry 5.0, offers tools and technologies that can significantly enhance your operational capabilities. From IoT devices that provide real-time data on machine performance to advanced analytics that offer insights into process improvements, technology can be a powerful ally in your quest for excellence.

Also, sustainability should be a key consideration in your operational strategy. As global awareness of environmental issues grows, manufacturers are increasingly expected to operate sustainably. This means not only reducing waste and energy consumption but also considering the entire lifecycle of your products. In integrating sustainable practices into your operations, you not only contribute to a healthier planet but also appeal to a growing segment of environmentally conscious consumers.

Finally, remember that the journey towards operational excellence is as much about people as it is about processes. Invest in your workforce through training and development programs that equip them with the skills needed to thrive in a rapidly changing industry. Foster a culture of collaboration and innovation where employees feel valued and empowered to contribute their ideas. By creating an environment where people are motivated to excel, you lay the foundation for sustained success.

To further solidify your journey, consider the importance of leadership in driving change. Leaders must not only endorse the vision but also embody it, setting an example for the entire organisation. They should be visible champions of the change, actively participating in initiatives and encouraging open communication. This leadership commitment is crucial in maintaining momentum and ensuring that operational excellence becomes ingrained in the company culture.

Additionally, consider the role of innovation in achieving operational excellence. Encourage your teams to think creatively and explore new ideas that could lead to breakthroughs in efficiency and quality. Innovation should not be confined to a specific department but should permeate every level of the organisation.

💡 Boost Your Business Performance Today!

Our Lean Coaching Programme has a proven track record of leading companies in operational excellence. Transform the way your business thinks and grows – the benefits are right at your fingertips.

More Blog Posts

To leave me a message or book a return call at a time that suits you