From Leadership to Line: The Modules That Build a Lean Culture

You’ve seen it, haven’t you? The frantic energy of a manufacturing floor that’s busy but not necessarily productive. The operators who know a better way to do things but have long given up trying to tell anyone. The managers who are buried in spreadsheets, chasing numbers that don’t seem to reflect the reality of the work. It’s a common story in UK manufacturing, this sense of running hard just to stand still.

This is where the idea of a Lean culture comes in. And I know, ‘Lean’ can feel like another one of those buzzwords that gets thrown around in boardrooms. But when you strip it back, a Lean culture is simply about creating an environment where every single person, from the CEO to the newest apprentice on the line, is actively engaged in making things better. It’s about a shared obsession with eliminating waste, solving problems, and delivering more value to the customer.

The real challenge, and where so many initiatives fall flat, is that you can’t just bolt it on. You can’t just train a few people in 5S, hang up some new charts, and call it a day. It has to be woven into the very fabric of your organisation. It requires a fundamental shift in mindset, starting at the very top and flowing all the way down to the person packing the final box.

So, how do you actually build that? It’s not about a single magic bullet. It’s about systematically putting in place the modules, the building blocks, that create a self sustaining system of continuous improvement. This is what we’re going to walk through today: the essential components that connect leadership’s vision to the powerful insights of your front line teams.

It All Starts at the Top: Leadership’s Unwavering Commitment

Let’s be brutally honest for a moment. If the leadership team isn’t genuinely, visibly, and consistently committed to this, you might as well not even start. I’ve seen it happen more times than I can count. A big announcement is made, a memo goes out, maybe there’s a budget for some training. And then… nothing. The directors go back to their offices, the managers go back to their old routines, and the message to the shop floor is loud and clear: this is just another flavour of the month.

True leadership commitment isn’t about signing cheques or approving projects. It’s about behaviour. It’s the managing director who puts on a pair of safety boots and walks the floor not on a planned tour, but just to observe and ask questions. And not questions like, “Why is this behind schedule?” but questions like, “What’s getting in your way today?” or “Is there anything that’s frustrating you about this process?”

This is about modelling the principles you want to see. If you’re talking about eliminating waste, leaders can’t be seen to be wasting people’s time in pointless meetings. If you’re talking about respect for people, leaders have to be the first ones to listen, truly listen, to the concerns of their team. Visibility is everything. When people see the boss taking the time to understand a problem at its source, it sends a powerful signal that this stuff actually matters.

And to be honest, leaders often need their own training for this. Their role in a Lean transformation is different. It’s less about having all the answers and directing traffic, and more about coaching, removing obstacles, and empowering their people. They need to learn how to ask probing questions that guide teams to their own solutions, rather than just prescribing a fix. It’s a shift from being the hero who solves the problem to being the leader who builds a team of problem solvers. Without this fundamental buy in and behavioural change at the highest level, everything else is built on sand.

The Human Engine: Empowering People and Breaking Down Walls

Once the leadership has set the tone, the real engine of any Lean culture is the people who do the actual work. Your front-line teams, your operators, your technicians, your warehouse staff. These are the people who live and breathe your processes every single day. They are the true experts. The person who has been operating the same machine for five years knows more about its quirks, its inefficiencies, and its potential than any engineer with a clipboard. Ignoring that expertise is, frankly, one of the biggest forms of waste in any business.

Empowering the front line isn’t just a nice phrase; it’s a deliberate strategy. It means giving them the authority and the tools to make improvements to their own work. It means trusting them. It means creating front line leaders, team leaders or cell leaders, who are not just supervisors but coaches and facilitators. Their job is to support their team, help them identify problems, and get them the resources they need to solve them.

But how do you tap into that wellspring of ideas? You have to create channels for communication that actually work. I’m sure we’ve all seen the dusty suggestion box in the corner of the canteen, a black hole from which no idea ever returns. That’s not what we’re talking about. We’re talking about structured, regular, and responsive feedback loops.

Daily team huddles are a brilliant place to start. A quick, 10-minute stand up meeting at the start of a shift around a visual management board. What did we achieve yesterday? What’s the plan for today? What problems are we facing? It creates a rhythm of communication and immediate problem solving. If a problem is raised, it’s not left to fester for weeks. It’s acknowledged right there and then, and an action is assigned.

This brings us to a critical point: you have to act on the contributions you receive. Nothing kills engagement faster than people offering ideas and hearing nothing back. Even if an idea isn’t feasible, closing the loop is essential. A simple, “Thanks for the suggestion, we looked into it, but we can’t do it right now because of X, Y, and Z” builds immense trust. It shows you’re listening. And when you do implement an idea, celebrate it. Publicly recognise the person or team who came up with it. It encourages others to step forward.

This principle of communication extends beyond individual teams. One of the most powerful modules you can build is a cross functional Lean Task Force. Pull together a small group of people from different departments: an operator from production, someone from quality, an engineer, someone from maintenance, maybe even a person from purchasing or sales. Get them to walk a process together, from start to finish. The revelations are often staggering. The quality inspector finally understands why the operator is struggling with a certain part. The production team sees how a small change they make creates a huge headache for the packing department. These collaborations break down the invisible walls and the “us versus them” mentality that kills efficiency. They uncover the hidden wastes that exist in the handoffs between departments, wastes that no single department would ever see on its own.

Building the Toolbox: From Training to Tangible Tools

A committed leadership and an engaged workforce are the foundation, but they need the right tools and skills to build with. This is where practical, hands on training comes in. And please, this cannot be death by PowerPoint. Lean is about doing. The best training gets people out of their chairs and into a simulated or real environment where they can apply the concepts immediately.

Workshops on specific Lean tools are essential. Think of things like:

- 5S and Visual Management: This is often the starting point, and for good reason. It’s about creating a clean, organised, and self-explanatory workspace. A place for everything, and everything in its place. When tools are easy to find, when problems are immediately visible (like a leak on a clean floor), and when standards are clear, it eliminates countless small frustrations and sources of waste. We’ll touch on this a bit more.

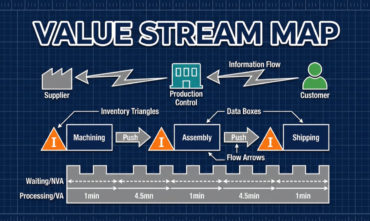

- Value Stream Mapping (VSM): This is like creating a map of your entire process, from raw material to finished product. It’s a powerful way to make everyone see the whole picture, not just their little piece of it. It brutally highlights all the non-value added steps, the waiting times, the unnecessary movement, and the bottlenecks.

- Problem Solving (PDCA, A3): You need to equip your people with a structured way to think about and solve problems. The Plan Do Check Act cycle is a simple but profound framework. It moves teams away from guesswork and firefighting towards a scientific method of defining a problem, testing a solution, measuring the result, and standardising what works.

The key is to start small. Don’t try to implement everything everywhere all at once. Pick a pilot area, a single production cell or value stream that has some challenges but also a willing team. Use it as your laboratory. Run the training, implement the tools, and work with that team to get a tangible win. This success story then becomes your internal case study. It builds momentum and creates a pull from other areas of the business who want to see the same results.

The role of a mentor or a ‘sensei’ can be invaluable here. Having an experienced guide, whether internal or external, who can coach the teams, ask the tough questions, and keep the focus on the core principles is often the difference between success and failure. This isn’t about having an expert who solves the problems for you; it’s about having a teacher who helps you learn to solve them for yourself. Capability building is the ultimate goal.

Making It Stick: Measurement and the Never-Ending Journey

So, you’ve got leadership on board, your teams are engaged, and you’re starting to use the tools. How do you ensure this isn’t just a temporary boost? How do you make it the new way of working? This is where measurement and a relentless focus on continuous improvement come in.

First, you need to be measuring the right things. Key Performance Indicators (KPIs) are crucial, but they need to be meaningful. Instead of just measuring overall output, start measuring things that reflect Lean principles. For example:

- Lead Time: How long does it take from a customer order to delivery?

- First Time Through (FTT): What percentage of products make it through the process without any rework or defects?

- On Time In Full (OTIF): Are we delivering what the customer wants, when they want it?

- Ideas Implemented: How many improvement ideas from the front line have we actually put into practice this month?

These KPIs should be visible to everyone, ideally on those team huddle boards. When people can see the direct impact of their improvement efforts on the numbers, it creates a powerful feedback loop that fuels more improvement.

This leads to the heart of a true Lean culture: the idea that you are never ‘done’. Continuous improvement, or Kaizen, is not a project with an end date. It’s a daily practice. It’s the constant, incremental refinement of processes. It’s the team on the assembly line figuring out how to shave two seconds off a task by repositioning a parts bin. It’s the maintenance team developing a new preventative check to stop a recurring machine fault.

These small, daily improvements, when compounded over time, lead to revolutionary results. The PDCA cycle becomes a habit. Teams are constantly running small experiments: “What if we tried doing it this way? Let’s test it for a week, check the results, and if it’s better, we’ll make it the new standard.” This is the engine that drives a Lean culture forward long after the initial consultants have gone home.

A System, Not a Shopping List

As we’ve walked through these modules, from the boardroom to the shop floor, I hope one thing has become clear. This isn’t a pick and mix menu. You can’t just implement a brilliant feedback system if your leadership isn’t listening. You can’t just run a 5S workshop and expect the culture to change if you don’t empower people to maintain the standards.

Each of these modules leans on the others. Leadership commitment creates the psychological safety for front line engagement. Engaged teams need feedback loops to be heard and cross functional collaboration to solve bigger problems. They all need the right tools and training to be effective, and they need clear measurements to see their progress and fuel the cycle of continuous improvement. It is a complete system.

Building a true Lean culture is a marathon, not a sprint. It takes patience, persistence, and a genuine belief in the potential of your people. The journey starts with a single, crucial step: a conversation among your leadership team about what kind of company you truly want to be. From there, by thoughtfully implementing these modules, you can build an organisation that doesn’t just survive, but thrives, by continuously getting better, every single day.

If you’re tired of chasing problems around the shop floor, maybe it’s time for something different. Our Lean Green Belt training could be that little nudge that actually makes a difference. If you’re even a bit curious click here and we’ll see where it goes.

More Blog Posts

To leave me a message or book a return call at a time that suits you