The £50,000 Question Kevin Didn’t Ask: Why Your Lean Program is Failing in Silence

The CNC machine whirs, spitting out another finished component. Kevin, the operator, picks it up and runs the callipers over it, just like he has a hundred times today. He frowns. It’s close. It’s probably fine. But it’s not right. It’s at the very edge of tolerance, and he knows that by the time this batch gets to assembly, a few of them are going to cause a headache.

He looks over at his supervisor, Dave, who’s hunched over a spreadsheet, looking stressed. The board on the wall shows they’re slightly behind schedule. Stopping the line now would mean a difficult conversation, a lot of paperwork, and a definite earful about hitting their numbers. Everyone saw this coming. The tooling has felt off for a week, but the last time someone mentioned it, they were told to just keep an eye on it. So, Kevin puts the component in the ‘pass’ bin, takes a deep breath, and lets the machine run. He keeps his mouth shut.

This tiny, silent moment is where Lean methodologies go to die. It’s where safety risks are born, where quality defects multiply, and where your continuous improvement culture grinds to a halt. The missing ingredient isn’t a better tool or a more colourful board. It’s something a lot more human. It’s called psychological safety.

In the simplest terms, psychological safety is the shared belief that it’s safe to speak up. It means people feel they can flag a problem, question a process, admit a mistake, or even float a half-baked idea without fear of humiliation, embarrassment, or being labeled a troublemaker. It’s not about being soft. It’s about being smart. It’s about creating an environment where people feel empowered to contribute their full potential without fear of negative consequences.

What Psychological Safety Is (and Isn’t)

Psychological safety isn’t about lowering standards or creating a fluffy, everyone-gets-a-trophy environment. It’s the opposite. It’s the foundation of high performance. It’s the team climate that allows people to meet high standards. How can you expect perfect quality if people are afraid to point out defects? How can you improve processes if workers don’t feel safe suggesting better ways? You can’t. You just get silence. And silence, in manufacturing, is expensive and dangerous.

This isn’t just opinion. Amy Edmondson at Harvard Business School has studied this for decades, proving its link to learning and performance. Google’s ‘Project Aristotle’ famously found that the number one predictor of a high-performing team wasn’t who was on it, but how they interacted. The most important factor? Psychological safety. More than free lunches or fancy perks, it was the shared feeling that “I can take a risk and speak my mind without being humiliated.”

Psychological safety isn’t about being nice. It’s about fostering respectful, candid, and fearless interaction. It’s the difference between a team that just follows instructions and one that actively solves problems. One is compliance. The other is commitment. As a manufacturer, you know which one you’d rather have.

Psychological safety also doesn’t mean avoiding accountability. In fact, it’s the opposite. It creates an environment where accountability thrives because people feel safe enough to take ownership of their work, admit mistakes, and learn from them. It’s about creating a culture where people are encouraged to bring their best ideas forward, even if those ideas challenge the status quo. It’s about fostering a sense of shared responsibility for outcomes, where everyone feels invested in the success of the team.

When psychological safety is present, teams are more likely to innovate, adapt, and perform at their best. It’s not just about avoiding mistakes; it’s about creating an environment where people feel empowered to take risks, try new approaches, and learn from failures. This is especially critical in manufacturing, where the ability to adapt to changing conditions and continuously improve processes can mean the difference between success and stagnation.

Why Your Lean Programme is Stalling Without It

You’ve invested in Lean. You’ve done the 5S audits, put up visual management boards, and trained people on A3 problem solving. But is it really working? Or has it become a performance? A kind of compliance theatre?

The boards are updated just before the manager’s Gemba walk. Team huddles are one-word updates with everyone staring at their shoes. The suggestion box is full of cobwebs. Performance improved for a while, but now it’s plateaued.

This happens when you implement the tools of Lean without building the underlying culture. Lean isn’t a set of tools; it’s a set of behaviours.

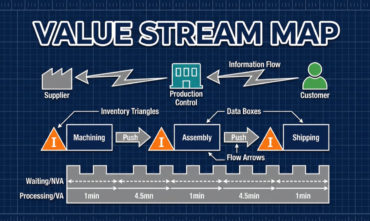

- Surfacing problems: Visual systems like Andon cords or SQDCP boards make problems impossible to ignore. But someone has to pull the cord or put a red magnet on the board. That’s an act of vulnerability, saying, “Something is wrong, and I need help.”

- Running experiments: Continuous improvement involves trying new things, many of which will fail. If failure is met with blame, no one will volunteer to try something new. People will stick to the old, inefficient ways because they’re predictable.

- Suggesting improvements (Kaizen): The best ideas for improving processes come from the people doing the work. But suggesting an improvement is implicitly a critique of the current process, which might be one their manager designed. It takes courage to say, “I think there’s a better way.”

- Learning from failure: A Lean culture asks, “Why did the process allow this to happen?” A blame culture asks, “Who did this?” One leads to learning and improvement. The other leads to hiding mistakes.

Without psychological safety, your Lean tools are just wallpaper. People will go through the motions, fill out forms, and update boards, but they won’t engage their brains. They’ll do the bare minimum to stay out of trouble. Your Lean initiative, meant to unlock potential, becomes another box-ticking exercise.

Lean is fundamentally about people. It’s about empowering the people closest to the work to identify problems, suggest improvements, and take ownership of solutions. But without psychological safety, this empowerment is impossible. People won’t speak up if they fear being blamed, ridiculed, or ignored. They won’t take risks if they believe failure will be punished. And they won’t engage in continuous improvement if they feel their ideas won’t be valued.

The Warning Signs and Costs of Silence

How do you know if you have a psychological safety problem? It’s rarely dramatic. It’s a collection of small, subtle signals. It’s the silence where there should be a question. It’s the workaround where there should be a root cause analysis.

Common warning signs include:

- Quiet Meetings: You ask, “Any problems?” and are met with silence. You know there are issues, but no one voices them.

- Blame Finds a Person, Not a Process: A defect gets through, and the first question is, “Who signed this off?” instead of, “What part of the system failed?”

- Shooting the Messenger: Someone raises a concern and is met with defensiveness or told, “We don’t have time for this.” They learn not to bother next time.

- The Hero and the Workaround: An operator is celebrated for keeping an unreliable machine running with workarounds. No one asks, “Why don’t we fix the machine?”

These aren’t just ‘people problems.’ They directly impact Safety, Quality, Delivery, Cost and People (SQDCP):

- Safety: Near misses go unreported. That wobbly pallet rack or small oil leak everyone steps over? People see them but don’t report them until they cause an accident.

- Quality: Kevin’s silence about the CNC machine translates into rework, customer complaints, and damage to your reputation.

- Delivery: Small issues grow into big ones that stop the line, causing unplanned downtime and missed deadlines.

- Cost: Rework, accidents, and downtime add up. So does employee stress, burnout, and turnover.

- People: People who don’t feel heard will leave, taking their skills with them.

The costs of silence are not just financial. They’re also cultural. A culture of silence breeds disengagement, mistrust, and apathy. It erodes morale and undermines teamwork. It creates an environment where people feel like cogs in a machine, rather than valued contributors to a shared mission. And over time, it drives away your best people—the ones who care enough to want to make things better.

How to Build Psychological Safety: Practical Steps for Leaders

This isn’t something you can fix with a memo or a poster. It’s built, conversation by conversation, by leaders on the shop floor. It’s about behaviours.

- Frame the Work as a Learning Problem: Acknowledge complexity. Say, “We’ve never done this exact run before, so we’ll need everyone’s eyes on it,” or “This is tricky; we’ll likely run into issues, and that’s okay.” This gives people permission to speak up.

- Respond to Bad News with Curiosity, Not Anger: If an operator says, “I think I’ve scrapped a pallet of parts,” fight the urge to react with frustration. Instead, say, “Thank you for telling me. Let’s look at it together.” This signals that bad news is valued.

- Model Fallibility: Admit when you don’t know something or make a mistake. Saying, “I messed that up, my apologies,” shows it’s okay to be vulnerable.

Embed these behaviours into existing Lean routines:

- On Gemba Walks: Use them to listen and learn. Ask, “What’s getting in your way?” instead of, “Why is this a mess?”

- In Daily Huddles: Ask, “What did we learn yesterday?” or “What’s one small thing we could fix today?”

- During Problem Solving: Focus on the process, not the person. Use the 5 Whys to find systemic causes.

Simple Starting Moves for Your Factory

This can feel like a big cultural shift, but you can start small:

- Weekly ‘No Blame’ Improvement Huddle: Pick one team. Spend 15 minutes discussing what went wrong that week, with a strict no-blame policy. The leader’s job is to listen, say thank you, and ask, “What’s one small thing we could try next week?”

- Visible ‘Bugs & Ideas’ Board: Create a board with two columns: “Things That Bug Us” and “Ideas to Try.” Leadership must review it daily and act on what’s there.

- Instil the ‘Thank You’ Habit: Train supervisors to say, “Thank you for speaking up,” whenever someone raises a problem or idea.

Start in one area. Measure the number of issues raised and improvements implemented. As safety increases, so will contributions. Use this data to spread these practices across the facility.

The Foundation You Can’t Ignore

Psychological safety isn’t a ‘soft skill.’ It’s the hidden infrastructure of operational excellence. You can have the best tools and processes, but if people are afraid to speak up, you’re operating with one hand tied behind your back.

Your people see problems and opportunities before you do. Unlocking that intelligence is your biggest competitive advantage. It starts with making it safe for them to speak.

Take a walk around your factory floor tomorrow. Look at the conversations happening—and the ones that aren’t. Ask yourself:

Where are people staying silent, and what is that silence costing us?

If you’re not sure of the answer, or don’t like the one that comes to mind, we can help. Our Lean Coaching and Mentoring Programme helps leaders foster a culture where problems are surfaced early, ideas are shared freely, and continuous improvement becomes a reality—not just a slogan.

More Blog Posts

To leave me a message or book a return call at a time that suits you