WINNING the Margins Game for Smart UK Manufacturers

Right then, let’s talk shop. If you’re in manufacturing in the UK right now, you don’t need me to tell you it’s a tough gig. It feels like you’re being squeezed from all sides. You have global competitors with lower costs, supply chains that have become ridiculously unpredictable, and energy prices that make you wince every time a bill comes through. It’s a constant battle. And in that battle, just staying afloat isn’t the goal, is it? The goal is to thrive, to grow, and to build something resilient.

The real secret to not just surviving but actually boosting your profit margins isn’t some mythical silver bullet. I have seen it time and again. It lies in something you already control: your processes. It’s about looking at how you do what you do, day in and day out, and asking, “Can we do this better?”. This isn’t just about cutting costs, though that’s a happy side effect. It’s about building a sustainable competitive advantage. It’s about becoming smarter, faster, and more efficient. Over the next few minutes, we’re going to walk through some innovative, yet practical, ways to improve your processes and, ultimately, your bottom line.

Why Process Innovation is Your Strongest Play

Let’s be honest, the term “process innovation” can sound a bit corporate and vague. Like something a consultant would put on a PowerPoint slide. But all it really means is finding new and better ways to get from raw material to finished product, and from a customer order to a happy delivery. It’s the ‘how’ of your business. And in manufacturing, the ‘how’ is everything.

For years, many of us manufacturers competed on quality, a sort of “Made in Britain” stamp of excellence. That’s still hugely important, of course. But today, it’s not enough on its own. Your customers expect that quality, but they also want it at a competitive price and with reliable delivery times. This is where your processes become your secret weapon. When you innovate your processes, you’re directly tackling the things that eat into your profit margins. Think about it. Every minute of wasted machine time, every product rejected by quality control, every hour an employee spends searching for a tool, that’s money walking out the door.

Improving your processes helps you reclaim that money. It reduces waste, cuts down on errors, and speeds up production. The knock-on effect is huge. Your market position strengthens because you can offer better prices, faster lead times, or both. Your capacity increases without necessarily needing to invest in a whole new factory wing. And maybe most importantly, your business becomes more resilient, better able to handle the shocks and surprises the world seems so fond of throwing at us lately. It’s about moving from a reactive position, constantly firefighting, to a proactive one where you are in control.

The Big Levers: Tech, Lean Thinking, and Your People

So, where do you start? It can feel overwhelming. I think the best approach is to focus on three core areas that provide the biggest bang for your money: technology, a lean philosophy, and empowering your team. They all feed into each other.

First up, let’s talk about automation and digitisation. For some, this conjures up images of giant, expensive robots replacing entire workforces. And while robotics are certainly part of the picture, that’s a very narrow view. Automation today is much more accessible. Think about using cobots, or collaborative robots, that work alongside your skilled staff to handle repetitive, strenuous tasks. Or what about quality control driven by AI? Imagine a camera system that can spot microscopic defects far more accurately and consistently than the human eye, 24 hours a day.

The benefits are pretty clear. You reduce costs tied to manual labour and human error. You increase throughput because machines don’t need tea breaks. I’ve seen companies slash their defect rates by over 90 percent simply by automating their inspection process. That’s a direct boost to the profit margin. It’s not about replacing people, it’s about elevating them. Let the machines do the dull, dangerous, and dirty work, and free up your skilled team to solve problems, innovate, and handle more complex, valuable tasks.

Next is lean manufacturing. This isn’t a new concept, but its power is timeless. At its heart, lean is simply a relentless war on waste. And waste is anything that doesn’t add value for the customer. This could be excess inventory sitting in a warehouse, tying up cash. It could be the time spent moving components from one side of the factory to the other. It could be overproduction, making more than you have orders for. The “just in time” production model is a classic example. Instead of stockpiling parts, you get them delivered exactly when you need them. This frees up an enormous amount of capital and space. I remember working with a mid-sized engineering firm implementing lean, something they fully embraced. Their shop floor was so clean and organised it felt more like a laboratory. They had cut their lead time from six weeks to just two, not by working their people harder, but by eliminating all the wasted steps in between. That’s how you win.

But here’s the thing. Neither amazing tech nor a perfect lean system will work without the third, most critical element: a culture of continuous improvement. Your best asset for spotting inefficiencies isn’t a high-priced consultant. It’s the person doing the job every single day. You need to empower your frontline workers to be your eyes and ears. Create systems where they can easily flag problems or suggest better ways of doing things, without fear of blame. Tools like Kaizen, which is really just a structured way of making small, incremental improvements, are fantastic for this. It’s about creating a mindset where everyone, from the CEO to the apprentice, feels responsible for making the business a little bit better, every single day. When your team is actively engaged in improving their own work, the results are transformative.

Smarter Structures for Growth and Stability

Once you start getting the factory floor in order, you can look at the wider business structure to find more opportunities for margin growth. This is about working smarter, not just harder.

A big one is outsourcing non-core activities. Ask yourself, what business are we really in? You’re in the business of manufacturing excellent products. You’re probably not in the business of being world class IT maintenance experts, or logistics gurus, or payroll administrators. These are vital functions, no doubt, but they aren’t your core competency. Outsourcing them to specialist firms can often be cheaper and more effective. More importantly, it frees up your time, your capital, and your best people to focus on what truly drives your competitive advantage: designing, making, and selling your products.

Hand in hand with this is standardising your core processes. This is where Standard Operating Procedures, or SOPs, come in. I know, SOPs can sound a bit rigid and bureaucratic. But a good SOP isn’t a straitjacket. It’s a recipe for success. It documents the best, safest, and most efficient way to perform a task. This has a massive impact on quality and consistency. It ensures every product that leaves your factory meets the same high standard, regardless of who was on shift. It’s also crucial for compliance and for scaling your business. If you want to train new staff or open a second production line, having well documented processes makes it a thousand times easier.

Don’t forget about the commercial side either. You can improve margins without even touching the production line by getting better at upselling and cross selling. Your relationship with a customer shouldn’t end when the product is shipped. That’s often just the beginning. Are you training your sales and service teams to proactively offer maintenance contracts, spare parts, or training packages? These after sales services often carry much higher profit margins than the original product. It’s about seeing every customer interaction as an opportunity to add more value, for them and for you.

Finally, think about strategic partnerships. In a complex world, you can’t do everything alone. Collaborating with key suppliers can lead to better raw material costs or joint innovation on new components. Partnering with distributors can open up new markets you couldn’t reach on your own. And what about technology partners? Working with a university or a tech startup could give you access to cutting edge R&D without the massive upfront investment. A joint venture might be the perfect way to develop a new product line and share the risk and reward. Strong partnerships build an ecosystem around your business that makes everyone in it stronger.

The Roadmap: From Idea to Reality

Okay, this all sounds good in theory. But how do you actually make it happen? Here’s a simple, practical roadmap.

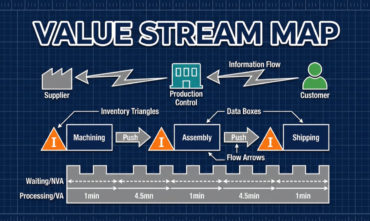

First, you have to analyse. You can’t improve what you don’t understand. Start by mapping out one of your key processes, from start to finish. Get the team involved. Use brown paper and sticky notes if you have to. Identify every single step, every handover, every delay. This alone is often a massive eye opener.

Second, identify the bottlenecks and waste. Where are things getting stuck? Where is time or material being wasted? Use data where you can. Measure cycle times, defect rates, and inventory levels. This is where you pinpoint the biggest opportunities for improvement.

Third, brainstorm and implement solutions. This could be anything from rearranging a workstation to investing in a new piece of software. Start small. Pick one or two high impact, low cost improvements to build momentum. This is crucial for getting team buy in. When people see that their ideas are being heard and that change is actually making their jobs easier, they get on board.

Fourth, monitor and measure. This is where Key Performance Indicators, or KPIs, come in. Track metrics like Overall Equipment Effectiveness (OEE), cost per unit, on time delivery rate, and, of course, your overall profit margin. You need to see if your changes are actually working. This isn’t a one time fix. It’s a continuous cycle. You analyse, you improve, you measure, and you do it all over again.

It Starts with a Single Step

Transforming your manufacturing processes to build a sustainable competitive advantage is a journey, not a destination. It won’t happen overnight. It requires commitment, a bit of investment, and a willingness to challenge the old “this is how we’ve always done it” mindset.

But the payoff is immense. We’ve talked about embracing technology and lean principles. We’ve covered the importance of building a culture where everyone contributes. We’ve looked at smarter ways to structure your operations and partnerships. Each of these strategies is a powerful tool for boosting your profit margins and securing your place in a competitive market. You don’t have to do it all at once. The most important thing is to start. Pick one area, one process, and take that first step.

The future of UK manufacturing belongs to the businesses that are agile, innovative, and relentless in their pursuit of being better. By focusing on your processes, you’re not just cutting costs; you’re building a stronger, more profitable, and more resilient company for the future.

Now, I’d love to hear from you. What are the biggest process challenges you’re facing in your business? What successes have you had? Share your thoughts in the comments below.

And if you need help getting started give us a call or contact us here.

More Blog Posts

To leave me a message or book a return call at a time that suits you