The difference between stagnation and growth often lies in mindset and management approach. The case of an SME Manufacturer with an £8m turnover, which lost a monumental £1.5 million order to a competitor that did not even manufacture but merely outsourced, illustrates a vital lesson in resilience, mindset, and strategic focus.

The Importance of Managing by Facts

Today’s manufacturing landscape demands a shift from traditional, often emotionally-driven decision-making to a more robust, evidence-based approach known as ‘managing by fact.’ This paradigm underscores the necessity of grounding decisions in data, metrics, and factual evidence rather than intuition, gut feelings, or emotions. It’s a shift that aims to heighten efficiency, enhance productivity, and foster innovation by making informed decisions that are aligned with strategic objectives and market demands.

Understanding ‘Manage by Fact’

‘Manage by Fact’ is not just a catchphrase; it’s a comprehensive approach that encompasses:

- Data-Driven Decision Making: Leveraging real-time data and analytics to guide strategic decisions, leading to more targeted and effective outcomes.

- Performance Metrics: Establishing clear, measurable objectives that help in assessing performance against goals, thereby facilitating continuous improvement.

- Objective Analysis: Encouraging a culture where decisions are made based on objective analysis rather than subjective opinion or hierarchical pressures.

The Power of a Growth Mindset

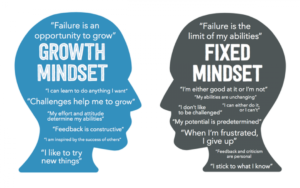

At the heart of the SME Manufacturer’s story is the concept of a ‘growth mindset,’ a term coined by psychologist Carol Dweck. It denotes an underlying belief that talents can be developed through hard work, effective strategies, and input from others as opposed to a ‘fixed mindset’ which posits that talents and abilities are static and unchangeable.

A growth mindset in manufacturing signifies:

- Embracing Challenges: Seeing failures, like losing a significant order, as opportunities to learn and evolve instead of insurmountable setbacks.

- Persistent Effort: Understanding that mastery and improvement require time, effort, and perseverance.

- Feedback and Critique: Welcoming constructive criticism as a resource for learning and development.

- Learning from the Success of Others: Viewing peers and competitors as sources of knowledge and inspiration rather than threats.

Combining Fact-Based Management with a Growth Mindset

The synergy between managing by fact and fostering a growth mindset can become a formidable strategy in manufacturing. Here’s how:

- Data-Driven Insights for Continuous Learning: Utilising data not just for operational decisions but for learning and development, aligning employee growth with strategic business goals.

- Metrics for Performance and Growth: Performance metrics and KPIs can serve dual purposes—measuring current productivity and efficiency while identifying areas for skill development and innovation.

- Adaptability through Objective Analysis: An objective, fact-based approach empowers teams to adapt swiftly to market changes, technological advancements, and competitive dynamics, fostering a culture of continuous improvement and agility.

The Story of Resilience and Adaptation

Returning to the narrative of the SME Manufacturer, the loss of a £1.5 million order could have been a crippling blow. However, the management and team’s growth mindset, coupled with a strategic focus on facts and data, turned a potential disaster into a learning opportunity. It pushed the company to analyse what went wrong, to understand the market and competitors better, and to refine its value proposition and operations accordingly.

Their journey underscores several key takeaways for manufacturers:

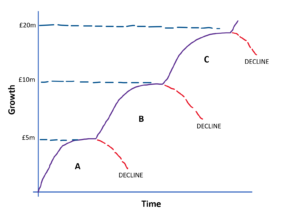

- Resilience is Key: The ability to bounce back from setbacks, powered by a belief in continuous improvement and the possibility of growth.

- Embrace Change: Being open to change and willing to adapt strategies based on what the data shows can differentiate between stagnation and growth.

- Collaborative Teamwork: A shared growth mindset within the team fosters collaboration, innovation, and shared ownership of both challenges and successes.

Conclusion: Forging Ahead with Facts and Growth

As the manufacturing sector continues to evolve amidst ever-changing market dynamics, the story of the SME Manufacturer serves as a compelling case study in the power of managing by facts not by emotion, and the transformative impact of a growth mindset.

Their experience illuminates a path forward for manufacturers seeking to navigate the complexities of modern-day business. It’s a dual approach where decisions are driven by data and insights, and where challenges and setbacks are seen not as endpoints but as stepping stones to greater achievements.

The manufacturers who will thrive are those who embrace the power of data, leverage the resilience of a growth mindset, and view every challenge as a new opportunity for growth and learning. Just as the SME Manufacturer demonstrated, the key lies in not just focusing on what to shrink but rather on what to grow. By striving to be better today than yesterday and planning to be better tomorrow than today, manufacturing businesses can ensure they remain competitive, innovative, and poised for success in an ever-evolving landscape.