Have you ever had the nagging feeling that your manufacturing business could be doing better? That despite your best efforts, you seem to be stuck in a rut, spinning your wheels without making significant progress, and watching as precious resources are squandered? You’re certainly not alone in this struggle. Across the UK, numerous small manufacturers grapple with the challenge of maximising efficiency and eliminating unnecessary costs that eat into their hard-earned profits. But there’s no need to despair because there is a powerful solution within reach that can totally transform your operations: the lean manufacturing approach.

Lean manufacturing isn’t just a set of tools or a temporary fix; it’s a comprehensive philosophy that, when embraced, can unlock the hidden potential in your business and turn what was once considered “waste” into pure gold. Allow me to guide you through this transformative philosophy and show you how to unleash a leaner, meaner, and more profitable manufacturing machine.

The Lean Mindset: Identifying and Eliminating Waste

At the very heart of lean manufacturing lies the relentless pursuit of waste elimination. But to tackle waste, we must first understand what it is. Waste in the manufacturing context can take many forms, such as overproduction, excess inventory, inefficient processes, unnecessary movements, waiting times, and defective products. Essentially, waste is anything that does not add value to your final product or service.

Developing a keen eye for waste is akin to developing a new sense of perception. It’s like decluttering your home – once you start identifying the unnecessary clutter, you begin to see it everywhere. And just like decluttering, eliminating waste in your manufacturing process can be incredibly liberating and empowering. It frees up space, resources, and energy, allowing you to focus on what truly matters: delivering value to your customers.

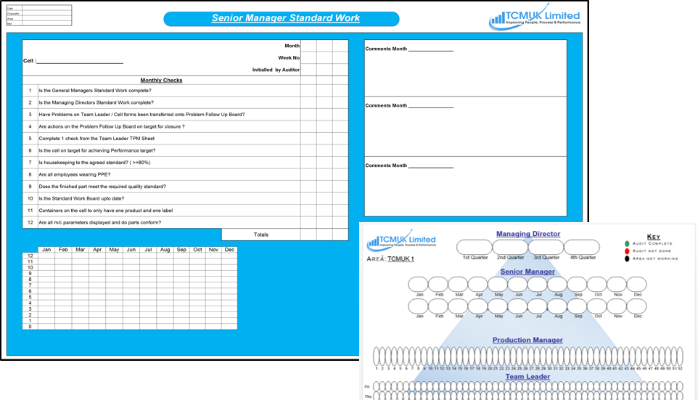

The Lean Toolbox: Unleashing Efficiency

With a clear understanding of what constitutes waste, the next step is to apply the power of lean manufacturing techniques. These tried-and-true tools are designed to streamline your operations and maximise efficiency. Let’s delve into a few of the game-changers that can revolutionise the way you work:

- Value Stream Mapping: This powerful technique allows you to visualise the entire flow of your manufacturing process, from raw materials to the finished product. By mapping out the value stream, you can identify bottlenecks, inefficiencies, and areas ripe for improvement. It’s a tool that provides a bird’s-eye view of your operations, highlighting where time and resources are being wasted and where the flow of production can be smoothed out.

- 5S: This lean principle (Sort, Set in Order, Shine, Standardise, Sustain) is all about creating a clean, organised, and efficient workspace. By implementing 5S, you’ll not only improve safety and productivity but also instil a sense of pride and ownership in your team. Each ‘S’ plays a crucial role: Sorting ensures that only necessary items are kept, Setting in Order arranges tools and materials for optimal workflow, Shining keeps the workspace clean, Standardising creates consistent methods and practices, and Sustaining ensures that these new standards are maintained over time.

- Just-in-Time Production: Say goodbye to excessive inventory and hello to a leaner, more agile manufacturing process. Just-in-Time (JIT) production ensures that you produce only what’s needed, when it’s needed, minimising waste and freeing up valuable resources. This approach requires precise planning and communication but, when executed correctly, can significantly reduce costs associated with storage and spoilage while ensuring that your products are always fresh and in line with current market demands.

Engaging Your Team: The Secret Sauce

The implementation of lean manufacturing techniques is just the beginning. To truly unlock the full potential of lean, you need to engage and empower your team. After all, your employees are the ones on the front lines, witnessing inefficiencies and waste firsthand.

Encourage your team to identify areas for improvement and share their ideas openly. Foster an environment where everyone feels valued and heard. When your employees feel invested in the lean process, they’ll become your biggest advocates and drivers of continuous improvement. This engagement leads to a more motivated workforce, one that takes initiative and pride in their work.

The Continuous Improvement Mindset: Lean is a Journey, Not a Destination

Lean manufacturing is an ongoing process, not just a single initiative. It requires a steadfast commitment to continuously identifying and eliminating inefficiencies and waste. To thrive, foster a culture of perpetual improvement where all team members proactively seek ways to refine processes and reduce waste.

Consider this as a constant cycle of enhancements, with each phase moving you towards a more streamlined, efficient, and profitable production process. This approach is essential as it keeps pace with ever-changing market conditions and technological advancements. By nurturing this dynamic culture, your business remains flexible, competitive, and at the forefront of industry developments.

The Benefits: Turning Waste into Worth

By embracing the lean manufacturing approach, you’ll unlock a host of benefits that can transform your small manufacturing business:

- Cost Reduction: By cutting out waste and enhancing efficiency, we directly lower our operational expenses, boosting our profit margins. Who isn’t pleased with more savings? These funds can be funnelled back into the company, propelling growth, spurring innovation, and enabling continuous enhancements.

- Quality Enhancement: Applying lean methodologies to pinpoint and rectify flaws boosts the quality of products, much to the delight of customers, thus delivering a dual benefit. This consistency in quality cultivates trust and loyalty, both of which are essential in the competitive landscape of today.

- Boost in Competitiveness: Speed and adaptability are crucial in the modern market, and lean manufacturing positions you to keep pace with market trends and supply products with more efficiency, giving your business a vital advantage over competitors. This nimbleness also makes adapting to shifts in customer tastes and market dynamics smoother.

- Employee Morale and Retention: Incorporating your team in the lean journey and valuing their input instils a sense of ownership and pride in their work. The outcome? Elevated job satisfaction and diminished staff turnover, particularly vital for smaller businesses. When employees feel engaged, they’re likelier to commit long-term to your company, cutting down the cost and interruption high turnover can create.

Embrace the Lean Mindset: Your Call to Action

Small manufacturers in the UK, the time has come to embrace the lean manufacturing approach and unlock the hidden potential within your operations. It may require an initial investment of time and resources, but the potential rewards are too significant to ignore.

Take the first step today by identifying areas of waste and inefficiency within your manufacturing process. Engage your team, implement lean techniques, and cultivate a culture of continuous improvement. Before you know it, you’ll be turning what was once considered “waste” into pure worth, propelling your small manufacturing business towards a leaner, more efficient, and more profitable future.

Embrace the lean mindset, and watch as your manufacturing operation transforms into a well-oiled, value-maximising machine. The time to unlock your hidden potential is now.

The Lean Transformation: A Detailed Roadmap

To embark on this lean journey, it’s essential to have a clear roadmap. This roadmap will guide you through the various stages of lean implementation, ensuring that you don’t miss any critical steps and that you can measure your progress along the way.

Stage 1: Assessment and Planning

The first stage involves a thorough assessment of your current operations. You need to understand where you are before you can chart a course to where you want to be. This assessment should be as comprehensive as possible, covering all aspects of your manufacturing process, including supply chain management, production, quality control, and delivery.

Once you’ve identified the areas that need improvement, it’s time to plan. Set clear, achievable goals for your lean transformation. These goals should be specific, measurable, attainable, relevant, and time-bound (SMART). With these goals in place, you can develop a step-by-step plan to achieve them, assigning responsibilities and deadlines to ensure accountability.

Stage 2: Training and Empowerment

Lean manufacturing is as much about people as it is about processes. For your lean transformation to be successful, your team must be fully trained in lean principles and techniques. Invest in comprehensive training programs that not only teach the tools of lean but also instill the philosophy behind it.

Empowerment is equally important. Your employees should feel confident in suggesting improvements and taking the initiative to solve problems. This empowerment can be fostered through regular team meetings, suggestion schemes, and recognition programs that celebrate the contributions of your staff.

Stage 3: Implementation and Monitoring

With your team trained and empowered, you can begin implementing the lean techniques you’ve chosen. Start with pilot projects or specific areas of your operations to test the effectiveness of the changes and to build momentum for a wider rollout.

Monitoring is critical during this stage. You need to track the impact of your lean initiatives to ensure they are delivering the desired results. Use key performance indicators (KPIs) to measure progress against your goals. These KPIs might include metrics such as production cycle times, defect rates, inventory levels, and employee engagement scores.

Stage 4: Review and Adjust

Lean is an iterative process. After implementing changes, take the time to review the outcomes. What worked well? What didn’t? What unexpected challenges arose? Use this information to adjust your approach and refine your processes.

This stage is also an opportunity to celebrate successes and to learn from failures. Both are invaluable in building a resilient and adaptable organisation.

Stage 5: Standardisation and Replication

Once you’ve found what works, standardise those processes so that they become the new norm. Document best practices and ensure that they are followed across your entire operation.

After standardising successful practices, replicate them in other areas of your business. This replication can lead to significant improvements across your organisation, multiplying the benefits of your lean transformation.

Stage 6: Sustaining the Gains

The final stage is about sustaining the gains you’ve made. Lean is not a set-it-and-forget-it approach; it requires ongoing attention and effort. Continue to monitor your KPIs, engage with your team, and look for new ways to improve.

Remember, the landscape of manufacturing is always changing. New technologies, materials, and market demands will present new challenges and opportunities. By maintaining a lean mindset, you can ensure that your business remains flexible, efficient, and competitive for years to come.

Key Takeaways

Transforming into a lean manufacturing enterprise comes with its hurdles. It demands dedication, strict adherence to principles, and openness to transformation. However, the benefits are undeniable: lower expenses, enhanced product quality, a boost in competitive edge, and a workforce that’s more involved and committed.

Being a UK-based producer, you stand at a pivotal moment to effect profound changes in both your enterprise and your sector. By adopting lean manufacturing practices, you can tap into the dormant capabilities of your processes, steering your company towards a future that’s streamlined, high-functioning, and financially rewarding.

The time to act is now. Embrace the lean mindset, engage your team, and start your journey towards excellence. Your business, your employees, and your customers will thank you for it. The transformation that awaits is not just about cutting costs or increasing efficiency; it’s about reimagining what your business can achieve. Lean is the key to unlocking a future where your manufacturing business doesn’t just survive but thrives.