Everyone works a process, from the team making the product or delivering the service to the Sales people engaging with new customers, everyone having their own Value-Added part to play in the smooth running of your business operations.

These processes need to be standardised in such a way they give a repeatable and reproducible output for scalability and growth, without blocking your innovation and continuous improvement.

We’ve streamlined business operations for Pensions, Redundancy, HR Systems, Manufacturing Operations, Legal Practices and many more, and we’ve yet to come across one that hasn’t improved by >25% in lead-time reduction and non-value-added activity.

Process Improvement is as targetable in back office operations and service processes as it is with manufacturing a product.

Process Improvement enables organisations to align business functions with customer needs, and helps determine how to deploy, measure and monitor the company’s resources. Process Improvement will increase efficiency and productivity, reduce costs, and minimise errors and risk – thereby optimising your results.

Expectations of your customers grow day by day, so it is important for your business to continually improve the quality of the products and services it has to offer. Your business can improve and secure its future by engaging in a process of continual improvement and adopting new processes of conformity assessment.

You need to continuously improve all areas of your business including; informed decision making, on-going investment, profitability, customer experience, Sales and Marketing and more.

Business Improvement Programmes

LEAN COACHING PROGRAMME

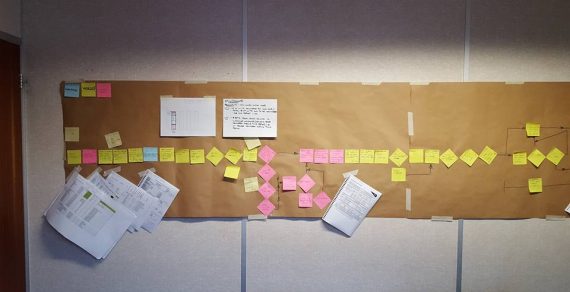

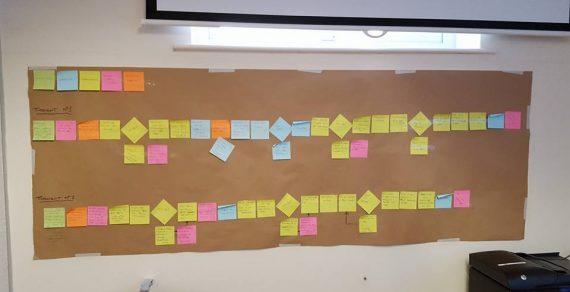

This programme helps you set the focus on the right things: performance improvement, problem awareness, solving problems the right way, and developing your people. Transform how managers think in order to grow a business designed for constant renewal and change through continuous improvement. Coaching and Mentoring programme working alongside your internal talent.

For more information Click here

PERFORMANCE IMPROVEMENT PROGRAMME

Short, High Impact project focussed on your specific area of need, this can be within both Production or Service environments, Manufacturing or Back-Office. Project examples include, HR Recruitment, Order Processing, Aftermarket Sales, Fleet Management, Legal, New Product Introduction, IT Systems, Value Stream Mapping, Quick Change-over, Layout Optimisation, VA-VE Events and many more.

For more information Click here

0330 311 2820

The many areas of Process Improvement are varied and each has its own specific purpose, understanding these areas is a particular speciality of ours.

Operational Systems Design

Process Foundations & Stability, Demand & Capacity Management (SIOP), Scheduling, Inventory Management and Logistics

Finance

Apply Process Improvement to the finance processes, such as accounting, controlling and reporting to optimise these processes.

Information Technology

To achieve the maximum benefit from technology, processes need to be streamlined, accurate and waste free. Businesses need to be strategic about the products and solutions they implement.

Sales and Marketing

The most essential elements are having a clearly defined vision for the business, a clearly defined strategy for each product or service offering and an action plan that turns vision into reality

Human Resources

For all organisations it is always important to perform its tasks and services in the most efficient way and to adapt continuously to new and increasing needs and requirements.

Engineering

VA/VE Workshops, NPDI Streamlining, Obeya Room Process are just some of the areas critical to an organisations engineering function.

Back-Office

Every person works a process. The aim is to ensure those processes are adding value. Back office processes are as targetable as any operation with 70% of the cost of a product associated to them.

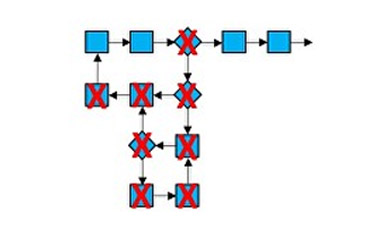

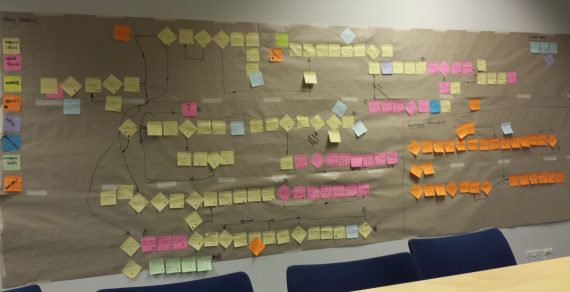

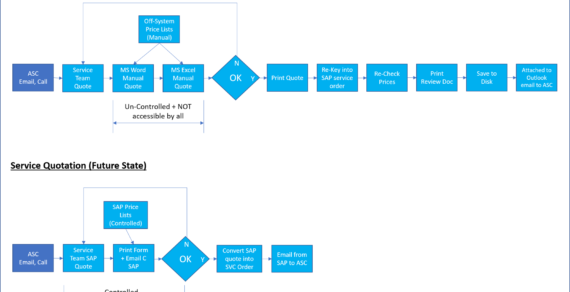

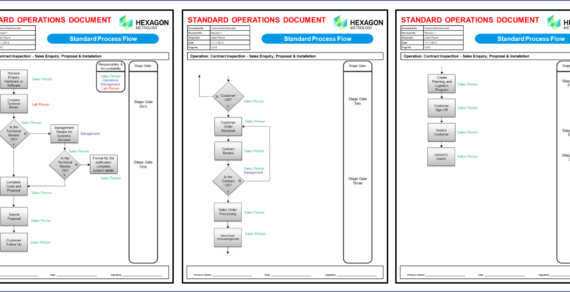

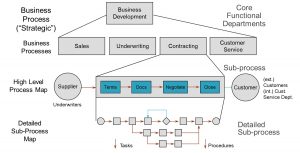

There are three views of a process

What you think it is…What it actually is…What it should be..

and there are different ‘flight levels’ within Process Improvement (see image below). The key thing to remember is ‘Reality is invariably different from perception; few processes work the way you think they do’ and ‘understand the process through facts and manage by fact’ that’s why we always follow the four stages below. Knowledge transfer and implementing best practice methods contributes to sound business management and provides transparency into how your organisation is meeting its goals.

Remember Y=f(X)

Where ‘y’ are your outputs (service, product) and ‘x’ are your inputs (business processes). Take waste out of your processes, (reducing variability, risk, increasing efficiency, etc) it directly impacts the ‘y’.