However, taking all those emotions in account, there is one thing for absolute certain, if Lean Thinking done well it delivers exceptional results. You must be committed with flawless execution and it’s not easy else everyone would be doing it.

if it’s done well it delivers exceptional results.”

Lean Thinking is not just a set of tools and techniques to be applied at every process within your organisation, this has a limited result! Lean Thinking is about changing the story of you, your business, your people and the community around you. It’s about learning, doing, problem solving, innovation, growth, strategy, looking at your business through your customers eyes.

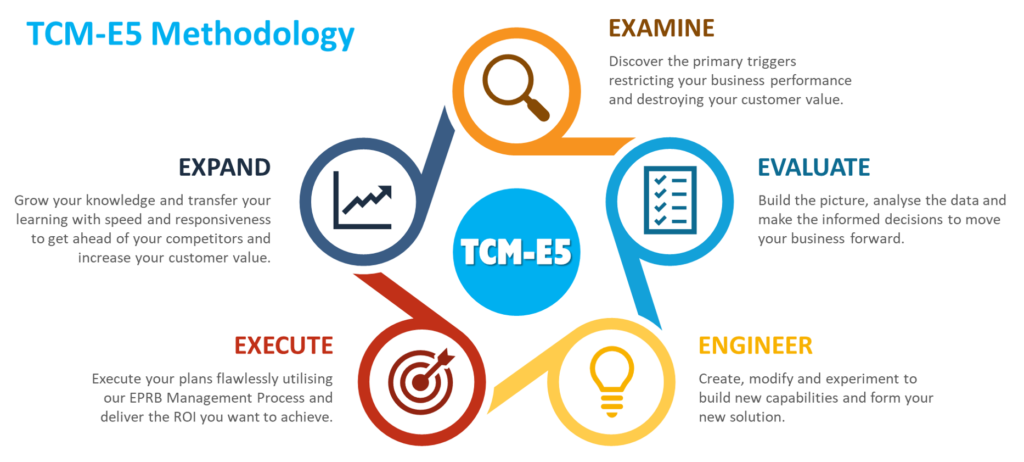

A Lean Strategy that develops your Competitive Advantage and Customer Value will make you more agile than your competitors and ensure year on year growth. Over the 25+ years working with Lean for Production and Services, Six Sigma and Theory of Constraints we have created our unique Lean Coaching Programmes and E5 Methodology (Examine, Evaluate, Engineer, Execute, Expand) that enhances your businesses DNA that delivers measurable and sustained business performance.

(to see our Lean Programmes ‘Click Here’)

Companies that fully commit to Lean and our E5 Methodology dramatically outperform their competitors over time. In getting as close as possible to where your work is being done, leading from the ground up to first find what your real problems are, you can then face and resolve the underlying challenges.

0330 311 2820

Lean Benefits – But how?

- Quality performance, fewer defects, errors and rework (internally & externally)

- Improved Work-Flow

- Lower Levels of Inventory

- Greater levels of Stock Turnover

- Reduced Lead-times

- Less Space Required

- Reduce Costs

- Higher efficiencies, more output per person hour

- Improved delivery performance

- Increased Agility and Flexibility

- Greater Customer Satisfaction

- Improved employee morale and involvement

- Improved Supplier Relations

- And more…

Our Lean Programmes

As part of our continuous support to the SME Sector we offer monthly payment plans on certain interventions to help spread your costs and manage cash flow. To qualify you have to be a SME with Fewer than 100 employees and a turnover less than or equal to £10 million. Potential Funding is available, terms do apply so please enquire.

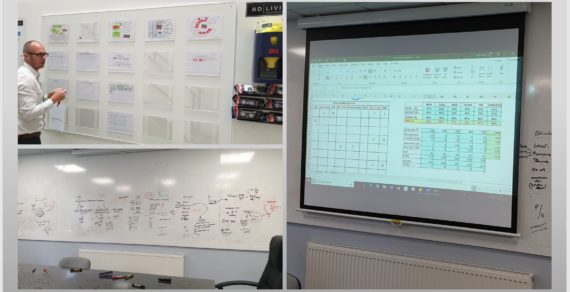

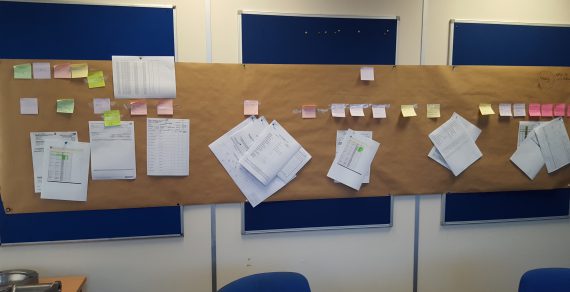

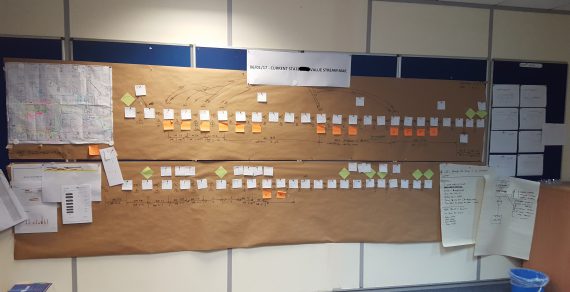

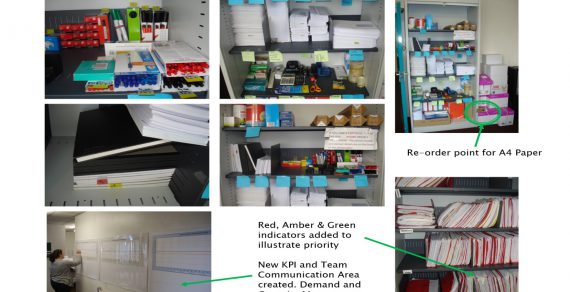

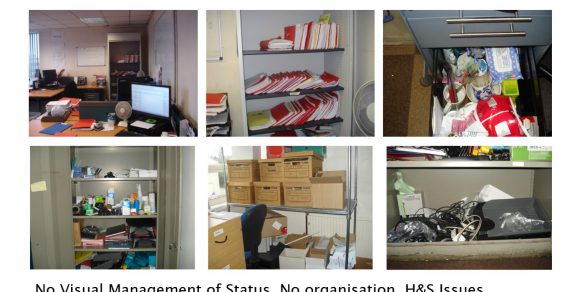

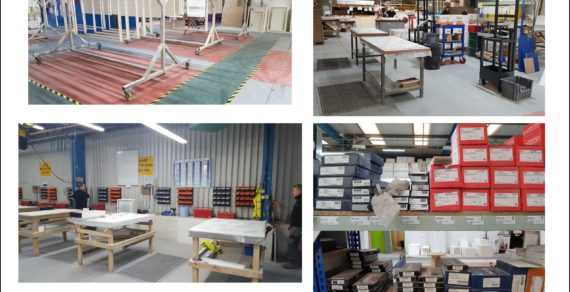

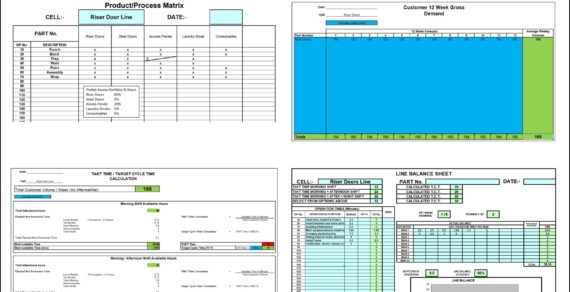

Photo’s of Customer projects can be seen at the bottom of the page, for our Case Studies ‘Click Here‘.

LEAN COACHING PROGRAMME

This programme helps you set the focus on the right things: performance improvement, problem awareness, solving problems the right way, and developing your people. Transform how managers think in order to grow a business designed for constant renewal and change through continuous improvement. Coaching and Mentoring programme working alongside your internal talent.

For more information Click here

PERFORMANCE IMPROVEMENT PROGRAMME

Short, High Impact project focussed on your specific area of need, this can be within both Production or Service environments, Manufacturing or Back-Office. Project examples include…

- 5S & Visual Management

- Value Added / Value Engineering

- Order Processing

- Achieving Quick Change-over

- Aftermarket Sales Process

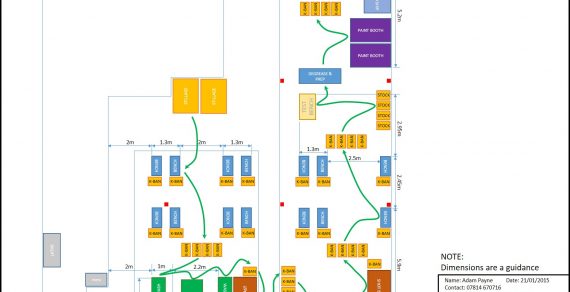

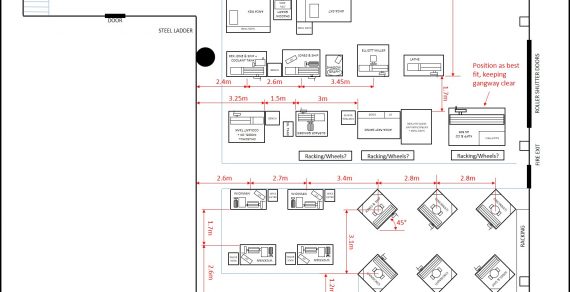

- Layout Optimisation

- Value Stream Mapping

- Streamlining Back Office Processes

- Contract Review

For more information Click here

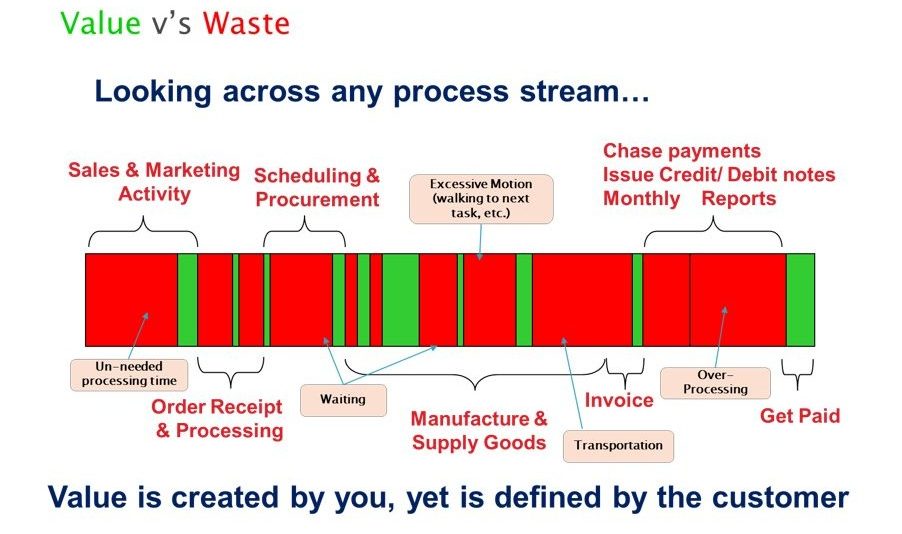

Everything you do must ADD CUSTOMER VALUE, If it DOES’T ADD VALUE IT’S WASTE. If it’s waste, it will impair delivery to the Customer. If it’s waste, it’s adding cost. If it’s waste, it’s causing frustration on the front line. Utilising our E5 Methodology (Examine, Evaluate, Engineer, Execute, Expand) mixed with Lean Strategies means you and your business maximise your opportunities in creating measurable and sustained business performance.

Recognising that “the market determines the selling price and that levels of profit are determined by your costs” is fundamental to understanding what is required to make a business successful. Look at your processes through your customers eyes, specifying value from your customers point of view.

If you can operate a system containing processes which achieve excellence in these 7 areas of performance…

…you can be confident that your company and its products/services will be able to compete in world markets. The operating processes of your business are the wealth-creating processes and also the processes which consume the majority of the resources, so they are a good place to start.

0330 311 2820