Operations system design for manufacturers has become a key issue in the manufacturing industry. This is because manufacturers are facing a lot of challenges such as increased competition, decreasing market share, supply chain issues, cost reduction and more.

Operations system design is a process or methodology that can help companies to improve their performance and achieve their objectives by implementing new strategies and processes on how they operate their business. It involves analysing the current performance of your company, identifying areas where improvement could be made and then developing solutions that will increase efficiency and profitability.

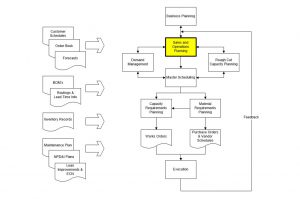

Some of the important concepts used in operations system design are the following:

Demand and Capacity Management

The demand and capacity management system are the main engine driving operations. It works by matching product demand with production capacity, which includes both production equipment and labour. The most important aspect of demand and capacity management is how it deals with shortages or excesses.

In a manufacturing environment, demand is often very unpredictable. This means that there are times when the factory needs more workers than normal, but also times when it has an excess of workers on its hands. Demand can also fluctuate depending on seasonality and other factors outside of your control as well as within your control (such as sales promotions).

The first step in creating a robust demand and capacity management system is to understand what drives your business and how this affects your supply chain requirements. For example:

If you’re making products on a seasonal basis, then you need to know when those seasons occur so that you can plan ahead for them.

If you’re planning sales promotions or other marketing initiatives, then you’ll need to know how many people will be needed to support these activities so that they don’t negatively impact production schedules or increase costs unnecessarily.

Planning and Scheduling

Planning and scheduling are the process of determining the activities or tasks to be performed, the sequence or order in which they are to be carried out, and the resources and time required for each.

Scheduling can be done manually or automatically. Scheduling systems can be used in manufacturing, warehousing, distribution, and other areas where work must be performed on a sequence of tasks that must be completed in a specific order. Manufacturing scheduling processes may include:

Multi-process workflow management — Scheduling of multiple processes to optimize resource utilisation and minimise total cost of operation.

Workload forecasting — Forecasting the amount of work that will need to be performed over time, so that sufficient resources can be allocated for production. (See our blog on Sales, Inventory and Operation Planning.)

Shop floor control — Monitoring the actual performance of each machine in the shop floor so that any bottlenecks or other problems can be identified quickly.

Scheduling optimisation — Using mathematical algorithms to find the best possible schedule for a given set of requirements.

(for automation visit FactoryIQ: What is a Manufacturing Execution System)

Operational Excellence in Logistics

Logistics is the management of the flow of goods between the point of origin and the point of consumption in order to meet customer needs. In terms of logistics, a product is a good or service with some utility to the customer. The term logistics comes from the Greek word logistikos, which means “skilled in calculating.”

Logistics involves the integration and synchronisation of all aspects of supply chain management. It includes planning, procurement, inventory control, production planning and control, distribution, packaging, order processing and shipping as well as associated financial services such as bill payment and revenue management.

Logistics is important because it is often an overlooked aspect in a company’s overall success, but it can also be an important part of any business model. A company that has effective logistics operations will be able to provide customers with products that they want at a price they are willing to pay while still making a profit. This allows a company to compete with other companies that may have lower prices or higher quality products but less efficient logistics operations.

Inventory Management

Inventory management is a system of control that determines the optimal location and quantity of inventory needed to minimise the cost of carrying that inventory. Inventory management is often used in conjunction with a Just-In-Time (JIT) or lean manufacturing system, which relies on careful monitoring of inventory levels to ensure that production lines are never interrupted by parts shortages.

Inventory management is usually accomplished through a computerised system, typically using barcode scanning technology to track individual items as they are received from suppliers and shipped out to customers. Inventory management also typically includes some form of point-of-sale (POS) software or hardware, which allows retailers to track sales and determine when sales goals have been met for each item sold.

The goal of inventory management is to reduce excess inventory while still meeting customer demand. These include:

Reducing Inventory Costs: Excess inventory can tie up valuable capital resources and increase carrying costs (i.e., storage space, insurance).

Minimising Out-of-Stock Situations: If a company has too little inventory on hand, it may not be able to meet customer needs. In addition, customers may perceive this as poor service or lack of concern for their needs.

Maximising Profitability: By keeping optimal levels of inventory on hand at all times, companies can reduce costly markdowns or write-offs due to excess stock in slow-moving items.

Process Stability

Process stability is the ability of a process to produce consistent product quality and quantity, on a day-to-day basis. It is a measure of how well the process delivers on its promise to produce the same product each time it is run. A stable process is one that can be relied upon to consistently provide high-quality, low-cost products.

Process stability is important because it affects both customer satisfaction and profitability. If customers are not satisfied with their product or service, they may find another supplier or stop buying altogether. If production costs increase unpredictably, profits will suffer as well.

Process stability also affects productivity levels and capacity planning, making it an important consideration for any manufacturing operation. Lean and Six Sigma methodologies say a big part here.

Process Foundations

A manufacturing operation is a system that transforms the materials and energy resources of the environment into finished goods and services. Manufacturing operations are divided into three main areas: processes, support functions and information technology (IT). Each of these areas has an impact on how efficient and effective your production system can be.

Processes

Processes include all activities that transform raw materials into finished goods or services. The processes themselves may be physical or organizational in nature. Physical processes include material handling, assembly, machining, painting, testing, and packaging. Organisational processes include planning, scheduling, forecasting, and controlling.

Support Functions

Support functions provide products or services to internal or external customers but do not directly produce finished goods or services. They include purchasing; quality; maintenance; engineering; human resources; finance/accounting; EH&S; supply chain management/logistics; information technology (IT); marketing, sales and many more (the complete value chain!).

Information Technology (IT)

Information technology is required to support many of these activities including: process control systems for manufacturing operations such as machine tool controls and robotics; ERP / MRP.

Takeaway: Operations Systems Design enables organisations to optimize the alignment of their processes, resources, people, and information systems.

PS: If you need support with Operations Systems Design or Lean Implementation please do get in contact.