Benefits of Sales and Operations Planning

- Increased customer service levels

- Improved profitability

- Reduced time to market with new products

- More products to increase revenue

- Lower inventories and obsolescence

- Reduced lead times

- Quicker responsiveness

- Top-down management control

- Predictable operating performance for shareholders

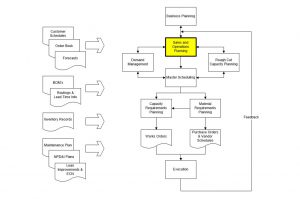

The Sales and Operations Planning process is the primary tool by which there is a systematic review of the business, out of which plans are established. It brings Sales, Marketing, Manufacturing and Finance together to agree on the volume of products to be produced over the next sales horizon. The process should be incorporated into the business calendar to coincide with the key activities of, strategic reviews, budget preparation, quarterly forecasting, monthly performance reviews and MRP/ERP timing.

Alignment from S&OP Process goes beyond just the meeting, the entire company is aligned to a given direction. This is one of the huge benefits from the S&OP Process. The Master Scheduler is implementing the decisions made by the S&OP team. The planners and buyers are aligning to the Master Scheduler. Capacity is being increased and decreased in accordance to the plan. Changes to the financial plan are made in advance given the decisions from the S&OP meeting. The monthly meeting allows for issues to be raised, tracked and resolved. Key department heads are present so that the entire company can be aligned behind a decision and as it is cascaded and communicated to the levels below.

The sales and operations plan looks 12 – 18 months into the future, this level of visibility opens the door to a different way of thinking: a longer term view. The process facilitates the bringing together of data from different departments and presents it to the team (Operations has visibility to Sales plans. Sales have visibility to the supply plan. Finance has visibility to expected revenues and expenses)

Finance are an integral part to making the process successful, they ensure the alignment of the financial plan to the operational plan so ultimately the objective of making money is achieved and on track. It’s no good planning to ramp up 30% if you only have the resources to ramp up 10%.

New product introduction (NPI) can be a headache (new suppliers, ramp up, technical issues, capacity, obsolete inventory, etc) but again the S&OP process facilitates the discussion. It enables all stakeholders to be aware when a new product introduction is happening. Sales needs to be talking to Operations. Operations needs to be talking to Finance. Many companies deal with NPI separately and have a project plan dealing specifically with new product introductions With NPI on the agenda within the S&OP process, issues can be raised, actioned and tracked, (releasing of capacity for trials, product traceability, etc) are managed carefully.

A big part of the S&OP agenda is reviewing the key business metrics in order to identify and resolve performance issues, when issues are raised, the key stakeholders are in the room to get things done.