How many times have you sat in a boardroom, looked at a beautifully crafted five-year strategy, and felt a genuine spark of excitement, only to see that spark fizzle out somewhere on the journey to the shop floor? It’s a story I’ve seen play out in manufacturing businesses across the UK. The ambition is there. The intelligence is there. But the connection between the grand vision and the daily grind of production targets, quality checks, and maintenance schedules gets lost in translation.

This isn’t a failure of ambition. It’s a failure of process. We create strategies in one room and expect them to be executed perfectly by people in another, often without a clear map connecting the two. It’s like giving someone a destination without a GPS, or even a paper map. They might get there eventually, but the journey will be inefficient, frustrating, and probably take them down a few wrong turns.

This is where a concept called Hoshin Kanri comes in. It’s a Japanese term that roughly translates to “compass management” or “shining metal pointing the way.” It’s a strategic planning and deployment methodology that was honed by companies like Toyota to create a direct, unbroken line from top level objectives to the everyday actions of every single employee. It’s not just another corporate buzzword. It’s a proven, structured way to make sure your strategy actually happens.

So, What Exactly is Hoshin Kanri?

At its heart, Hoshin Kanri is a systematic approach to ensure that the goals of a company are the driving force behind the actions of every person within it. It originated in post war Japan, a time when companies had to be incredibly resourceful and focused to rebuild and compete globally. They couldn’t afford wasted effort or internal misalignment. They needed a way to point everyone in the same direction, and Hoshin Kanri became their compass.

It’s built on a few core principles that, frankly, just make sense.

First, there’s alignment. This is the big one. Hoshin Kanri creates a clear cascade of objectives. The company has a long-term vision, which is broken down into a handful of critical “breakthrough” objectives for the next three to five years. These are then translated into specific, measurable annual objectives. And those annual objectives are then broken down further for each department, each team, and ultimately, each individual. Everyone can see how their work directly contributes to the bigger picture. The person calibrating a machine on the night shift understands how their precision impacts the company’s goal of becoming the market leader in quality.

Second, there’s engagement. This isn’t a top-down dictatorship. One of the most powerful parts of the process, which we’ll get to, is something called “Catchball.” It’s a back-and-forth dialogue. Senior leadership proposes the objectives, but then they toss them to the teams who have to deliver them. Those teams toss back their feedback, their ideas, and the resources they’ll need. This dialogue ensures that goals are realistic, and more importantly, it creates a deep sense of ownership. People support what they help create.

And third, there’s continuous improvement, or Kaizen. Hoshin Kanri isn’t a “set it and forget it” plan. It’s a living, breathing system. You are constantly checking your progress against your targets through regular reviews. This isn’t about blaming people when things go off track. It’s about asking “why?” and learning from the process. It builds a culture where problems are seen as opportunities to get better, not mistakes to be hidden.

The 7 Steps to Making Strategy Happen

Okay, so how does this actually work in practice? The Hoshin Kanri planning process is often broken down into seven steps. It looks like a lot on paper, but think of it as a logical flow from a big idea to daily reality.

- Establish Your Organisational Vision: This is your North Star. Where do you want your business to be in ten years? This shouldn’t be a fluffy mission statement. It needs to be a clear, compelling picture of the future. Something like, “To be the UK’s most trusted supplier of high precision aerospace components, known for zero defect quality and on time delivery.”

- Develop Breakthrough Objectives: You can’t do everything at once. Based on your vision, what are the three to five game changing things you need to achieve in the next three to five years? These are your “breakthroughs.” They should be bold. Examples could be: launching a fully automated production line, reducing lead times by 50 percent, or entering a new European market.

- Set Annual Objectives: Now you break it down. To make progress on that 50 percent lead time reduction, what do we need to achieve this year? Maybe the annual objective is to “Reduce average order fulfilment time from 20 days to 15 days by December 31st.” It’s specific, measurable, and time bound. You’ll have a few of these, each one directly supporting a breakthrough objective.

- Cascade Objectives (The ‘Catchball’ Process): This is where the magic happens. Senior management doesn’t just email these annual objectives out. They present them to their direct reports, the department heads. They ask, “Here’s what we need to achieve. How can your department contribute, and what do you need from us?” The production manager might say, “To hit that 15-day target, I need to reduce machine changeover time. I think we can get it down by 10 percent this year. To do that, I’ll need a budget for new tooling and two days of training for my team leaders.” This conversation, this negotiation, and coaching, goes all the way down the organisation. It’s a game of catch, not a command.

- Implement and Execute: Once the objectives are agreed upon at all levels, it’s time to get to work. Because of the Catchball process, everyone knows what they need to do and why they are doing it. The plan isn’t some abstract document; it’s a shared commitment.

- Monitor Progress (PDCA): This is the heartbeat of Hoshin Kanri. You use regular, structured reviews to check your progress. Many teams use the Plan Do Check Act cycle. You had a Plan (reduce changeover time). You Did the actions (bought the tools, ran the training). Now you Check the data. Did changeover time actually decrease? If yes, great. If not, you move to the final step.

- Reflect and Learn (The ‘Act’ part of PDCA): If you missed the target, you don’t just try harder. You analyse what happened. Was the training ineffective? Was the new tooling wrong? You adjust your approach based on what you’ve learned. This is how you embed continuous improvement. If you hit your target, you standardise the new, better process and look for the next improvement. This cycle of review and adjustment happens monthly, sometimes even weekly.

Why This is the Key to Real Growth

I’ve worked with manufacturers who had brilliant engineers and dedicated teams, but they were spinning their wheels. Different departments were pulling in different directions, often with good intentions. The sales team would promise a quick turnaround to win a big order, not realising the strain it would put on a production team already struggling with an outdated machine. Hoshin Kanri fixes this.

It creates organisational focus. Suddenly, everyone is rowing in the same direction. When a new project or request comes up, you can hold it up against the Hoshin plan and ask, “Does this help us achieve our annual objectives?” If the answer is no, it’s easier to say no, or to at least question its priority. It stops the organisation from getting distracted by “flavour of the month” initiatives.

The engagement it fosters is transformative. I saw this at a mid-sized engineering firm in the Midlands. They were struggling with morale and high staff turnover on the factory floor. After we implemented the Hoshin Kanri concept, and specifically the Catchball process, team leaders started contributing ideas that management had never even considered. They felt heard. They felt valued. Within a year, their productivity metrics had improved by over 15 percent, but more importantly, their staff retention shot up. People weren’t just coming to work for a pay cheque; they were coming to work to help the company win.

This leads to measurable, sustainable improvements. Because everything is tied to data and regular reviews, you move beyond guesswork. You know what’s working and what isn’t. One of the classic examples is the Danaher Corporation, a global science and technology conglomerate famous for its operational excellence. They built their entire legendary business system around the principles of Hoshin Kanri. It allowed them to acquire companies and rapidly deploy their improvement methodology, driving incredible growth and shareholder value year after year. They live and breathe by the data, and it all starts with their strategic deployment process.

The Tools That Make It Work

This all sounds great, but how do you manage it all without drowning in spreadsheets? There are a few key tools that help.

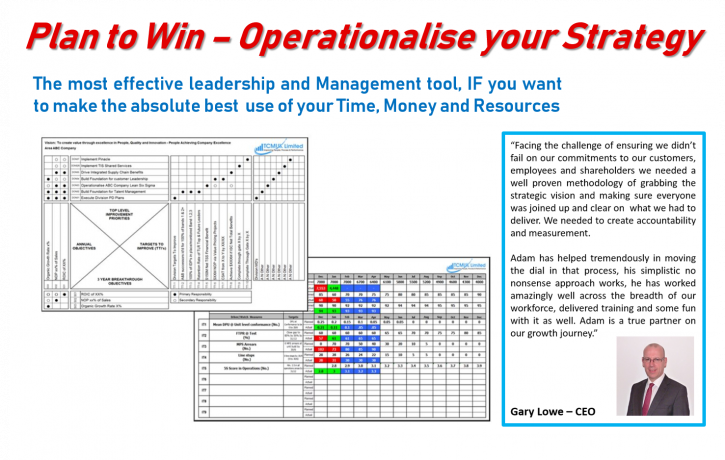

The most famous is the Hoshin Kanri X-Matrix. It looks a bit complicated at first, but it’s a brilliantly simple one-page document. It visually connects your long-term breakthrough objectives, your annual objectives, the specific improvement priorities for the year, and the key metrics you’ll use to measure success. It even shows who is responsible for what. It’s a powerful tool for showing the entire plan on a single sheet of paper, making the connections obvious to everyone.

The other core tool is the PDCA Cycle (Plan-Do-Check-Act). This isn’t just a Hoshin tool; it’s the foundation of all modern continuous improvement. But within Hoshin, it provides the engine for the review process. Each improvement initiative, from the departmental level down to a small team project, is managed through this cycle. It ensures that you aren’t just “doing stuff,” but are doing it with a clear hypothesis (Plan), testing it (Do), measuring the results (Check), and then learning and adapting (Act).

Overcoming the hurdles is crucial. The biggest challenge is always leadership commitment. If senior leaders aren’t driving the review process and living by the plan, it will fail. It can’t be delegated to the quality department. Another common issue is poor communication during the Catchball process. It needs to be a genuine dialogue, not just a briefing. Finally, reviews can become inconsistent. If you start skipping the monthly reviews because you’re “too busy,” the whole system falls apart. The discipline of the review process is non-negotiable.

The key to overcoming these is to start small. Maybe pilot the process in one department. Get some quick wins, show people how it works, and build momentum from there. And be patient. This is a cultural shift, not an overnight fix. It takes time to build the habits of data driven review and open dialogue.

Your Compass for the Future

Implementing a system like Hoshin Kanri is a serious commitment. It requires discipline, honesty, and a willingness to change how you think about strategy itself. But the transformation is profound. It’s the difference between having a strategy that sits on a shelf and having a strategy that lives and breathes in the daily actions of your entire workforce.

It aligns your people, focuses your resources on what truly matters, and builds a resilient culture of continuous improvement that becomes your ultimate competitive advantage. In a world of volatile supply chains, skills shortages, and intense global competition, having a reliable compass to guide your organisation isn’t just a nice to have. It’s essential for survival and growth.

If you’re ready to stop letting your strategy get lost in translation and start driving real, measurable performance, it might be time to look at Hoshin Kanri.

To see how we can help you implement a robust strategic planning process in your organisation, click here to see our Strategic Deployment Programme.