In the realm of business operations, there’s a significant gap between perception and reality. Processes rarely function the way we think they do, and this discrepancy can lead to a host of inefficiencies and frustrations. To understand why this happens and how we can address it, let’s delve deeper into the nature of business processes, the common pitfalls, and the strategies for effective process optimisation.

Understanding Business Processes

A business process is a set of activities or tasks that, when performed, will accomplish a specific organisational goal. Examples of business processes include writing a report, manufacturing a product, or managing a new client. Each of these processes involves a series of steps that need to be executed in a particular order to achieve the desired outcome.

However, the reality is that few processes work the way we think they do. This misalignment between perception and reality is often the root cause of inefficiencies within an organisation. For instance, you might think that writing a report is a straightforward task, but in reality, it involves multiple steps such as data collection, analysis, drafting, reviewing, and finalising. Each of these steps can introduce delays, errors, or other issues if not managed properly.

The Consequences of Inefficient Processes

Inefficient processes can lead to a myriad of problems that affect both the internal workings of a business and its external interactions with customers. Some common consequences of poorly managed processes include:

- Unhappy Customers: When processes are inefficient, customers may experience delays, errors, or poor service quality. This can lead to dissatisfaction and a potential loss of business.

- Missed Deadlines: Inefficient processes can cause delays that result in missed deadlines, which can tarnish a company’s reputation and lead to financial penalties or lost opportunities.

- Invoicing Mistakes: Errors in invoicing can lead to financial discrepancies, disputes with customers, and a loss of trust.

- Poor Quality: Inefficient processes often result in lower quality outputs, which can affect the overall performance and competitiveness of a business.

That’s why it is so important to improve processes when they are not working well.

The Role of Technology in Process Improvement

Now in the age of Technology Innovations, businesses often turn to IT systems to improve their processes. While technology can certainly streamline operations and enhance efficiency, it is not a panacea. The adage “garbage in, garbage out” is particularly relevant here. If the underlying process is flawed, implementing an IT system will merely automate the inefficiencies rather than eliminate them.

Our focus should always be to systemise processes, but remember the process is the solution and also the problem.

In understanding a process recently, over 40% of production management time was chasing parts, that ripple effect is massive, (throwing a stone on one side of an ocean can cause a tidal wave on the other). Now in understanding the process we found that certain bits of information were being omitted. The business process is flawed. If we design the IT system without first understanding and optimising the process, the IT system we implement will be flawed as well.

It might make things easier, but long term, you’re never going to get the best results, because the underlying process isn’t up to scratch.

Based on our experience/research you can expect a 25%+ improvement within a process by focusing on optimisation.

This improvement can manifest in various ways, including:

- Reduced Cycle Time: Streamlined processes can reduce the time required to complete tasks, leading to faster delivery and increased productivity.

- Enhanced Quality: By eliminating inefficiencies and errors, optimised processes can produce higher quality outputs, resulting in greater customer satisfaction and reduced rework.

- Cost Savings: Efficient processes can reduce waste, lower operational costs, and improve profitability.

- Improved Employee Satisfaction: When processes are efficient, employees can focus on value-added activities rather than being bogged down by unnecessary tasks, leading to higher job satisfaction and morale.

So, fix your processes, then systemise them, because doing it the other way around will almost always cause headaches.

Implementing Process Optimisation in Your Organisation

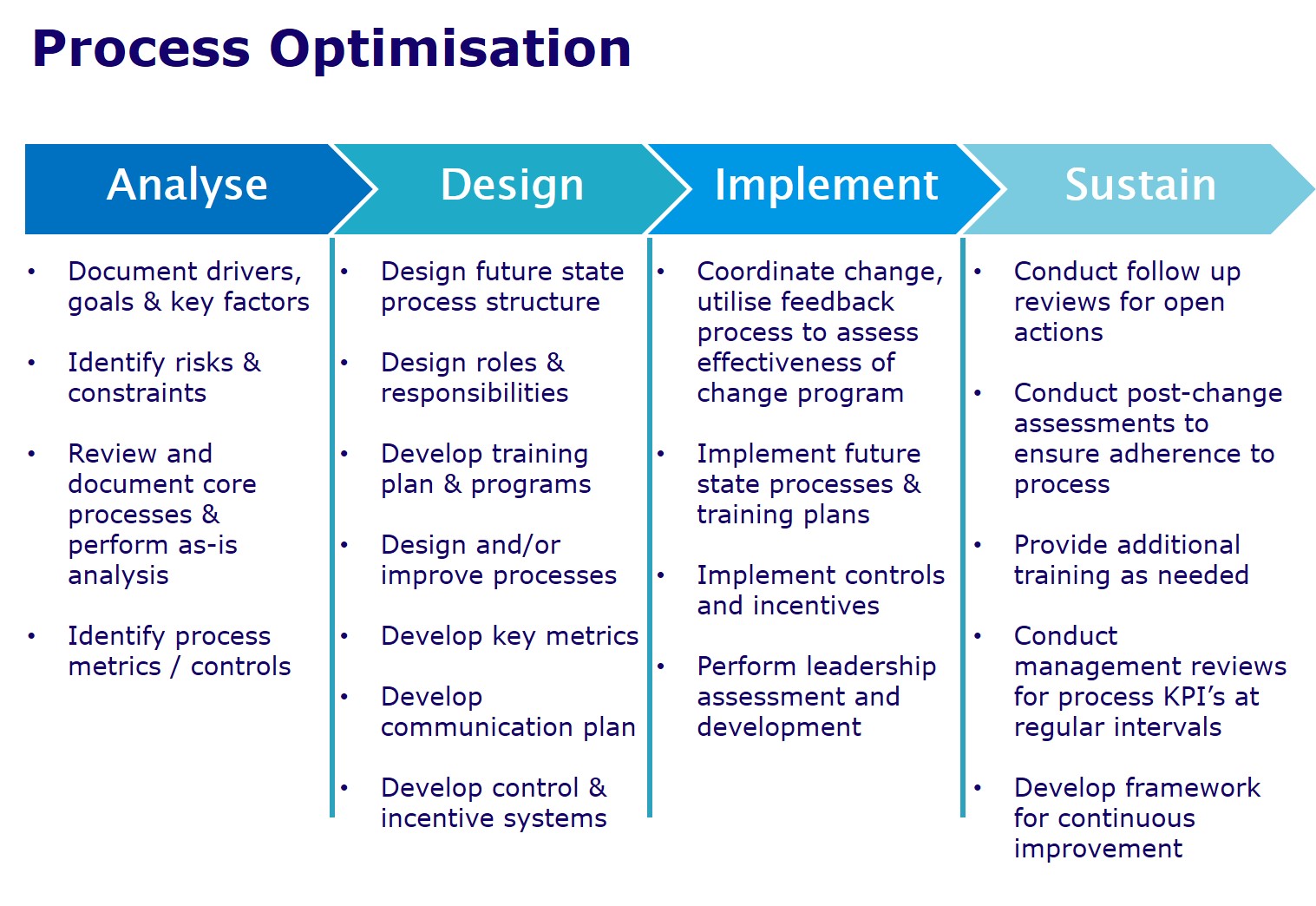

To successfully implement process optimisation in your organisation, consider the following steps:

- Conduct a Process Audit: Start by conducting a comprehensive audit of your existing processes. Identify key areas of inefficiency, gather data on performance metrics, and solicit feedback from stakeholders.

- Engage Stakeholders: Involve key stakeholders in the process improvement initiative. This includes employees who are directly involved in the process, as well as managers and executives who can provide strategic direction and support.

- Develop a Clear Plan: Create a detailed plan for process optimisation, outlining the steps to be taken, the resources required, and the expected outcomes. Set clear goals and timelines to ensure accountability.

- Implement Changes Gradually: Implement changes incrementally rather than attempting a complete overhaul all at once. This allows you to test and refine the new process, making adjustments as necessary based on feedback and performance data.

- Monitor and Adjust: Continuously monitor the performance of the optimised process and make adjustments as needed. Establish key performance indicators (KPIs) to track progress and ensure that the process remains aligned with organisational goals.

- Leverage Technology: Once the process is optimised, consider leveraging technology to further enhance efficiency and streamline operations. This could include implementing automation tools, workflow management systems, or data analytics platforms.

Conclusion

In conclusion, the process is both the problem and the solution. Inefficient processes can lead to a host of issues, including unhappy customers, missed deadlines, invoicing mistakes, and poor quality. However, by focusing on process optimisation, businesses can achieve significant improvements in efficiency, quality, and profitability.

At TCMUK Limited, we have seen firsthand the transformative impact of process optimisation. By conducting thorough process audits, engaging stakeholders, and implementing targeted improvements, we have helped numerous organisations streamline their operations and achieve better outcomes. Remember, the key to success is to understand and optimise the process first before implementing any technological solutions. This approach ensures that the underlying process is robust and capable of delivering the best possible results.

For more information on how we can help your organisation optimise its processes, please contact us at 0330 311 2820 or visit our website. Sharing is caring! If you found this article helpful, please share it with your network.