Benefits of Policy Deployment

- Organisations with the capability to consistently execute their plans through the adoption of Strategy Execution outperform the market.

- Organisational capabilities will be aligned to support the achievement of your company objectives.

- Resources will be allocated to business processes in priority order (according to the importance/contribution the process makes to your business)

- Your company can excel in the business/commercial sector in which it operates.

The Policy Deployment process has yielded some unbelievable benefits for me in my career and it’s one of those processes I recommend all businesses leaders introduce, (but I will also state if you are not prepared to apply the rigorous PDCA management process that goes with it, it’s not for you). I’ve been using Policy Deployment for 15+ years across multiple businesses, as an example: £1bn Turnover business, achieving £200m EBITDA across 38 sites globally, including Lean Savings within the first year of £21m. Done well, it works!

Some of you are probably getting to the stage or are currently producing budgets for your coming year. Now wouldn’t it be worthwhile aligning your Strategy and your budget requirements and drive some break through thinking into the process.

The process itself comes from a technique called Hoshin Kanri, which is a method devised to capture and cement strategic goals, well for me it does more that cement goals, it disseminates those goals into tactical projects that are owned, timed bound and measured.

There have been a number of English translations Policy Deployment, Goal Deployment, Hoshin Planning. I prefer Policy Deployment Process or PDP, but as you probably know from me by now, call it what you want just as long as you use it.

So What DOES it do?

- It forces the clear identification of “How” we move ourselves towards our Strategic objectives.

- It creates an alignment of all facets of the organisation on the key strategic initiatives (cross-functional teamwork).

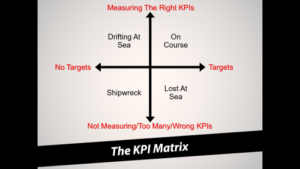

- Fosters a data-oriented, fact-based culture.

- Reinforces the vision, but also clearly defines how we will get there (Based on “Who” does “What”).

What it DOESN’T do!

- Achieve results if the management process isn’t changed (Moved to rigorous PDCA).

- Achieve results if the “How’s” (Improvement Priorities) aren’t the right ones.

- Achieve results if the “How’s” aren’t clearly defined.

- Replace the need for solid Business Fundamentals (also known as Daily Management).

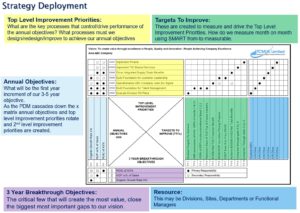

The process is intended to help an organisation:

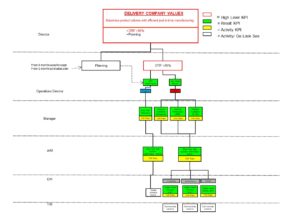

take the Company Vision (desired end state, aspirations, business scope); the Strategy (3-5 Year Strategic gaps/objectives, high level plans for competitive advantage) and creates a One year distillation of these 3-5 year objectives.

It creates improvement priorities and metrics for tracking progress and indicates the resource responsible and accountable for them. A tactical implementation project if you like (you can go further with the process and state which projects need to be completed within each quarter of the year, to add additional focus).

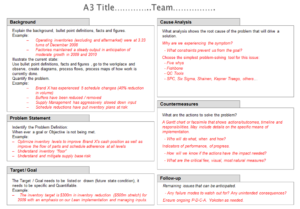

Detailed action plans (A3’s) are produced for each one of the improvement priorities and reviewed on weekly/monthly/quarterly basis through monitoring of the PDP metrics.

These reviews should be held by a cross functional team who challenge each other, learn from each other and drive execution of the improvement priorities.

Typical Strategy Objectives may be:

- Double Top Line Sales in 5 yrs

- Double OP % to Sales in 3 yrs

- Reject PPM Reduction by 90% in 3 yrs

- Reduce Lead-time by 75

- On Time Delivery to 100% in 3 yrs

Typical Annual Objectives may be:

- Grow Top Line Sales by 15%

- Increase OP by 25%

- Reject PPM Reduction by 50%

- Reduce Lead-time by 50%

- OTD +20%

Improvement Priorities may be:

- Quality: Create & Implement Rapid Defect Reduction Process, Implement DFSS on Critical Products

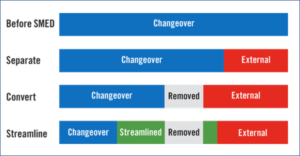

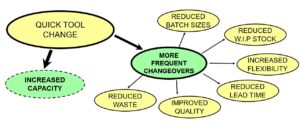

- Delivery: Apply Lean ‘Tools to XYZ to Reduce LT, Implement Back-Office LT Reduction Process

- Cost: Develop & Implement LCR Sourcing Plan, Launch Productivity Improvement Std Work Series in Assembly

So Why Use it?

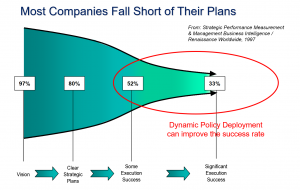

97% of Businesses have a Vision

80% have a clear Strategic Plan

52% some Execution/Success

33% Significant Execution Success

Where do you think Policy Deployment is having an Effect?