Lean Manufacturing is a culture and a strategy. It’s a way of doing things that helps companies improve efficiency, quality, and flexibility. It’s not just about tools and processes—it’s about people, too.

Lean Manufacturing is all about making things more efficient. It focuses on eliminating waste and finding ways to streamline workflows so that the company can produce more with less time and money.

Create a Lean Manufacturing culture

A Lean Manufacturing culture is an environment where people are taking responsibility for their own improvement, the improvement of processes and products, and the overall improvement of the company. It’s a culture built on trust, accountability, and continuous improvement.

In order to create this culture, it’s important to give employees the freedom to make decisions about how they do their job and then hold them accountable for those decisions. This can be tricky if you’re not sure what your employees’ strengths are or how they work best. But one way to develop this understanding is by asking questions like: “What’s been most helpful in improving your efficiency?” or “What practices have helped you achieve your goals?”

Once you’ve identified some of these practices, try them out on other employees! Make sure they’re working before adopting them as official company policy though—you don’t want anyone feeling like they’re being punished just because they weren’t included in testing new ideas before implementation!

Have the Upper Management Lead by Example

Lean is a powerful strategy, but it’s not something that can be implemented overnight. In order to make the most of your Lean efforts and get the most out of your employees, it’s important to have upper management lead by example.

Upper management should be actively engaged in the process of implementing Lean, from the beginning to end. They should also be involved in training new employees on Lean’s principles and ensuring that everyone is working together toward common goals. This will help employees understand how important their role is in helping you achieve those goals, which will increase their sense of ownership over their work.

Upper management should also be willing to let go of their preconceived notions about how things should be done in favour of allowing employees more freedom when it comes time to make decisions about how tasks should be completed.

Train your Team on Lean Basics

One of the best ways to get your team on board with Lean is to train them on the basics.

The Lean principles are not complicated, but they can be difficult to understand if you’re new to the concept. You should prepare your team by giving them a solid understanding of what Lean is and why it’s important before you start putting it into practice.

If your team doesn’t have a clear understanding of the principles, they will have trouble implementing them into their day-to-day work. If, for example, if you try to reduce waste without first explaining what waste is and why it needs to be reduced, then you’ll find that the effort isn’t effective or sustainable.

This is especially true when it comes to engaging your employees in Lean initiatives: if they don’t understand why they should participate in these efforts and how they’ll benefit from doing so, then they won’t be motivated enough to participate fully or consistently.

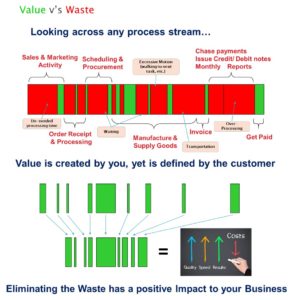

Value Stream Map – Study the Current Process

The first step in implementing Lean is to study the current process. This will help you identify areas of improvement and determine whether or not you are ready for the changes that will be necessary to make this happen. You can do this by performing a value stream map, which is a visual representation of your workflow.

The process should be broken down into steps. You want to look at each step and ask yourself what can be done to improve it, and how this change might affect other parts of the process as well. It is important to consider how each step impacts other steps, so you can look at all aspects of your operations and make sure that they are working together effectively.

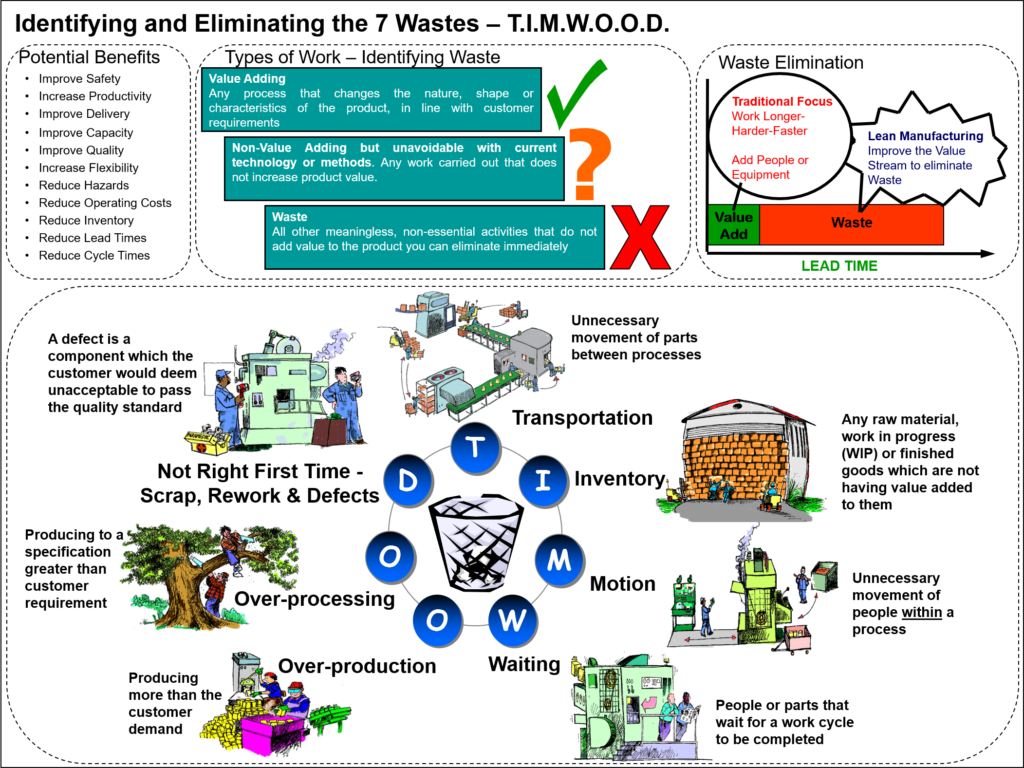

Look for Waste and Remove It (Muda – Waste, Mura – Unevenness, Muri – Overburden)

You can define waste as anything that detracts from the value of a product or service you’re producing from your customers’ point of view. Waste can take many forms, such as overproduction, unnecessary resources, and more. These things need to be eliminated so that organisations aren’t creating products or services that don’t add value.

Muda is any kind of wasted motion, such as unnecessary steps in a process or unnecessary travel between locations. Mura refers to unevenness in the production line—it means one part of the process might be operating at peak efficiency while another part is idle or struggling just to keep up. Muri refers to overburdening people with too much work—this is often seen when you have an employee working alone on a task that should be split between two or more people to match customer demand (TAKT).

Map out the Main Bottlenecks

The main bottlenecks in a process are the aspects of the system that are limiting its throughput.

In order to identify these, you’ll need to first look at or build your Value Stream Map or Process Map and identify where there are bottlenecks. Then, you can work on fixing them by identifying what’s causing the bottleneck and finding ways to remove it. This may involve making changes like adjusting how people work together, reducing change-over times, increasing the Overall Equipment Effectiveness or changing how tasks are assigned (e.g., having workers perform different parts of a task).

Once you’ve identified where your bottlenecks are, you can start working on removing them.

Standardise Everything

This means that you need to define what “standard” means, and then make sure all employees are aware of it and trained to it. Standardising your processes gives consistency in how your team members perform their tasks.

For example, if you’re a software company and you’re trying to improve efficiency by standardising on coding practices, then every employee should know which practices are allowed and which are not allowed.

You should also standardise your equipment and tools. If multiple employees use the same equipment or tool, everyone should use it in the same way every time.

If your company has multiple locations, then standardising everything is even more important because it helps create consistency between locations. If everyone knows what standards they need to meet at each location, then they’ll be able to work together better across locations knowing the desired quality will always be met.

Develop a Continuous Improvement Mentality

Implementing lean means shifting your focus from your business’s outputs to its inputs. But if you’re going to do that, you need to first develop a continuous improvement mentality.

To do this, you have to be willing to adopt an attitude of continuous improvement and continuous learning. You need to be constantly looking for ways that you can improve how things are done in your office or factory and how they contribute to the overall success of your business.

You also need to be willing to consider new ideas, because one of the main tenets of lean is that there are no bad ideas—only challenges in implementation. If someone suggests something new or comes up with a way of doing something differently, try it out! Even if it doesn’t work right away, you may learn something valuable about how something works or doesn’t work within your organisation.