Optimisng Layout and Flow

Business Objective

“As turnover increases and we use more space we need to control it better, 5S is a requirement whilst also looking into the 7 Wastes within our operations/processes.

Our main product ‘A’ is approximately 70% of our production and I would like to stabilise the operation and also increase our current output. Lifting of the product is a concern from an H&S point of view and a potential for increased damage.

I would like to start developing the team in thinking about Lean Manufacturing, reducing waste and costs.” – Managing Director

(35% Funded Support on this project, click here for Interventions in Scope)

Current Situation and Background

Main Assembly is a manual operation, layout of material and consumable stock has no flow. Items cannot be found easily and makes material handling a cause for H&S concern.

Analysis shows that material and people movement is excessive due to lack of 5S and Visual Management within the area.

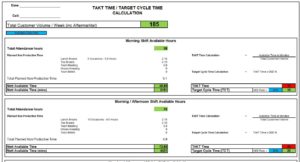

- Takt and timings not understood for product ‘A’

- Planning has some logic applied based on system data and knowledge of the process.

- There are a total of 15 people in the assembly area with all or none working on Product ‘A’

- Current 5S score is 19/120

- Cycle Time of 38 minutes for Product ‘A’

Analysis and Recommendations

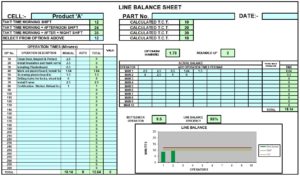

Flow diagrams were created for the current layout as well as demand analysis, timings and TAKT understanding. New layouts were discussed and drawn, and the first phase of Point of Use/5S Implementation began.

Implementation and Achievements

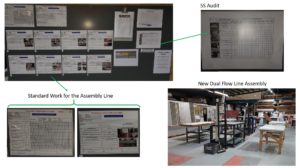

New layouts and Visual Management were implemented, along with a new method of manufacture for the assembly line of product ‘A’.

Standard Work instructions were introduced, as well as a Visual KPI Board, 5S Board and general communications.

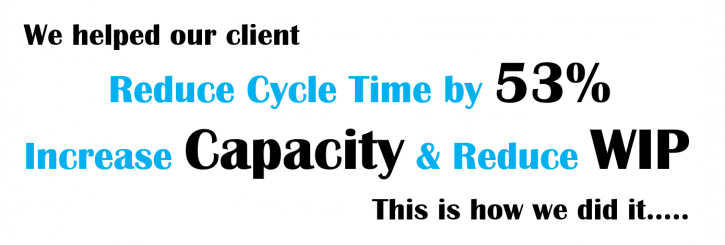

Business Achievements

- 50% reduction in lifting/material handling

- Increased Capacity, resulting in 30% Increase in Output

- Reduced Manufacturing Footprint

- Reduced Work-in-Progress

- Line balanced for 2 People to deliver Customer Demand

- 53% Improvement in Cycle Time for Product ‘A’

- 93% Improvement in Distance Travelled

- Standard Work Introduced

- Visual Management and Point of Use Introduced

- 5S Score increased from 19/120 to 87/120

“We have recently completed a “Lean Program” within our business. We have been supported by Adam Payne (TCMUK Limited) who came along to our business and was able to offer excellent suggestions and ideas for improvements. He delivered various training sessions with the business, he drove the team for synergy and was very supportive.

We have reduced our waste by 93% and increased our efficiency by 53% which would not have been possible if it wasn’t for the support we received from Adam Payne (TCMUK Limited)”

Kevin Paterson – Operations Director

0330 311 2820