He knew that the team on Mill 3 was waiting for materials that should have arrived an hour ago. He knew the pallets stacked by the shipping door were for an order that had been reworked twice, shredding its profit margin. He knew his best supervisor was spending his entire day chasing problems instead of training his people.

The day before, he’d gotten a call from his biggest customer. The tone was friendly, but the message was clear. Lead times were slipping. They were “exploring other options”.

Jason felt a knot tighten in his stomach. He wasn’t just losing efficiency. He was losing control. And he was terrified he was about to lose the business he’d spent his life building. He looked at all the motion, all the effort, and saw the truth. It was waste. Not just the scrap in the bin, but wasted time, wasted talent, and wasted potential.

Does any of this sound familiar? Maybe not the specifics, but the feeling.

That nagging sense that your team is working hard, but you’re not getting ahead. The frustration of solving the same problems over and over. The pressure of knowing you could be faster, better, and more profitable if you could just get out of your own way.

To be honest, that feeling is normal. But it isn’t necessary.

The problem isn’t your people or your work ethic. The problem is the system. You’re too busy fighting fires to redesign the factory so it’s fireproof.

This training is the blueprint for that fireproof factory. It’s not just about learning theory. It’s about giving you and your team a new way of seeing your business, so you can stop managing chaos and start leading growth.

Does Any of This Sound Familiar?

Let’s be honest for a second. That dream of a perfectly streamlined plant can feel a million miles away. Your reality is probably closer to this:

- That sinking feeling when you see the scrap bin is full. Again.

- The same preventable problems cropping up week after week, no matter what you try.

- Knowing your team is capable of so much more, but they seem stuck in a cycle of rework and frustration.

- The constant, grinding pressure on margins from wasted time, materials, and energy.

- Lying awake at night thinking about a late order or a looming quality issue, feeling like the entire weight of the factory is on your shoulders.

This is where you trade daily fire fighting for deliberate, relentless improvement. It’s a hands-on, practical program designed specifically for the realities of the manufacturing floor. We skip the corporate fluff and get straight to the tools and thinking that will make a tangible difference to your bottom line, your team’s morale, and your own peace of mind.

A Straightforward Investment in a Calmer, More Profitable Future

We believe in transparency. No hidden fees, no surprise charges. Just a clear, high value investment in the future of your business. We come to your site and train your entire team at once, creating instant alignment and momentum.

Course curriculum includes…

LEAN GREEN BELT TRAINING

Lean Principles and Implementation.

5S and Visual Management

Autonomous Total Productive Maintenance (TPM)

Features and benefits of a Kanban/Pull

Understand the concept of Quick Changeovers

Top-level SIPOC and Process Map Techniques

Problem Solving and Cause & Effect Tools

Failure Mode Effect Analysis

The Role of Quality

Standard Work

A3 Problem Solving.

Managing Daily for Improvement

Overall Equipment Effectiveness

The Requirements of Lean and People.

On-site for up to 12 Candidates

3 Day Lean Green Belt Training

£2999

4 Day Green Belt Training

(Includes Manufacturing Simulation Game)

£3899

(All price Excl. VAT and Travel)

Think about it for a moment. What’s the real cost of one major quality escape? One lost customer due to a late shipment? One more year of the same inefficiencies? This isn’t an expense; it’s one of the highest ROI investments you’ll ever make in your people and your processes.

This is More Than Just a Certificate. It’s a New Reality.

Forget dry bullet points about curriculum. Let’s talk about what actually changes after this training.

- You’ll turn chaos into calm. No more running around chasing parts or information. You’ll learn to build visual systems where problems reveal themselves before they become crises, giving you that feeling of control you’ve been missing.

- You’ll stop losing entire shifts to changeovers. We’ll show you the SMED playbook that turns hours of downtime into minutes of productive, profitable uptime. Suddenly, you have the flexibility to take on smaller, high margin jobs your competitors can’t touch.

- You’ll transform your team from employees into problem solvers. This isn’t about telling people to “work harder.” It’s about empowering them with the tools (like A3 Thinking and 5S) to fix the frustrating issues they face every day. The result? A team that takes ownership.

- You’ll become the supplier your customers brag about. Imagine being known as the company that delivers on time, every time, with impeccable quality. That’s how you stop competing on price and become an indispensable partner your customers can’t imagine leaving.

Why TCMUK Limited?

Expertise

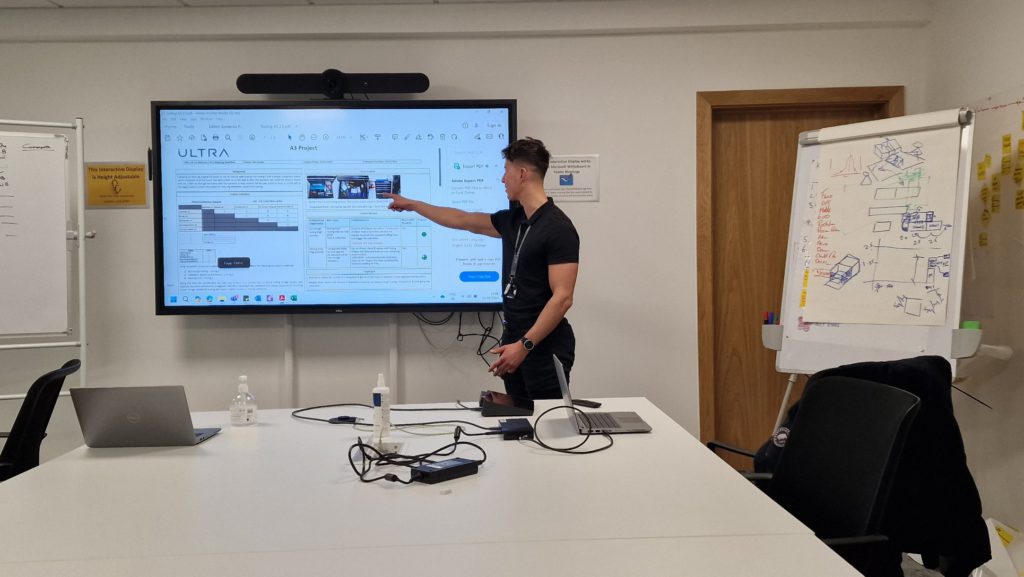

What sets us apart is our in-depth knowledge of all the necessary techniques. We focus on leveraging hands-on learning experiences to ensure that participants grasp the underlying principles and can apply Lean effectively within their operational tasks.

Testimonials

Our former participants commend us for our articulate delivery, ability to add value through robust tools and strategies, and our supportive nature. We are not just your trainers; we are your mentors, guiding you throughout your Lean journey and beyond.

Affordability

High-value knowledge does not always have to equal high cost. Our course offerings are competitively priced, with potential funding opportunities and monthly payment plans available.

Invest in the Lean Awareness Program and take the first step toward a transformed, more productive future of your business, where waste reduction and maximisation of value go hand in hand.

“Adam has recently facilitated Lean Training for our factory Team Leaders and he demonstrated both first-rate understanding of the subject and excellent engagement with the participants. I would have no hesitation in whole-heartedly recommending Adam to any company looking to up-skill its workforce in lean techniques.”

David McGee – Operations Manager

0330 311 2820